Dec 25, 2023 | Articles

Dermatological formulas are essential for companies that specialize in topical pharmaceuticals. The development of these formulas requires a great deal of expertise and experience. It is important to understand the complexities of producing these formulas in order to craft effective products that meet the needs of consumers.

At Dow Development Labs, we work with clients to develop and manufacture dermatological formulations based on their specific needs. We use our extensive knowledge of skin biology, chemistry, and pharmacology to create highly effective topical products that are safe and efficacious for consumers. Our team has experience in developing a wide range of dermatological products, including creams, lotions, ointments, gels, serums, solutions, sprays and shampoos.

When working with us on a dermatological product formulation project we will start by understanding your desired outcome for the product as well as any specific requirements you may have relating to efficacy and safety standards. We will then carry out detailed research into the latest advances in skin science as well as exploring the performance characteristics required by today’s consumers before creating a prototype product formulation that meets your objectives.

We also offer method development services which help us identify key parameters such as pH values or viscosity measurements needed for optimal performance when applied topically to skin surfaces. In addition we can also advise on packaging requirements and labelling regulations applicable within different regions or countries ensuring you meet all necessary standards prior to launch.

Once all necessary tests have been completed we can move onto full-scale product manufacturing where our state-of-the-art equipment ensures customers receive quality products quickly and efficiently at competitive prices without compromising on efficacy or safety requirements. As part of our quality assurance process we will also provide customers with detailed documentation regarding each stage of production from raw material specifications through to finished product testing results; enabling customers to make informed decisions about their products prior to launch into the marketplace.

At Dow Development Labs we understand the importance of outsourcing your topical pharmaceutical development projects effectively so you can focus on commercializing successful dermatological products quickly without compromising safety or efficacy standards; allowing you more time to concentrate on other areas such as marketing or distribution channels which may be critical for success in today’s competitive marketplaces. Our experienced team has an impressive track record developing high quality formulations with consistent performance profiles that meet customer objectives while adhering strictly to national regulatory requirements; ensuring customer satisfaction every time!

If you’re looking for an experienced laboratory partner who can help craft effective dermatological formulas through topical pharmaceutical development contact us today at Dow Development Labs where our experts will be happy assist you with achieving your goals!

Dec 18, 2023 | Articles

Topical products are an essential part of the pharmaceutical and scientific development landscape. Over the years, these products have been refined and improved upon, with greater emphasis placed on stability and performance. Now, pharmaceutical companies and scientific development companies are looking for ways to enhance the stability and performance of topical products even further.

One of the most successful approaches to achieving this goal is partnering with a laboratory that specializes in product development, method development, packaging, labelling and/or product testing. By working with an experienced laboratory that has a strong background in topical product development, pharmaceutical companies can ensure their products are as effective as possible while also being cost-efficient. This type of collaboration can result in improved stability and performance for topical products.

When considering which laboratory to partner with for formula development, method development, packaging or labelling services, it is important to consider factors such as experience level, customer service capabilities and trustworthiness. It is also important to find a laboratory that is not only capable of providing quality services but also one that is willing to go above and beyond when it comes to meeting customer needs. For instance, Dow Development Labs focuses on providing exceptional customer service by taking a collaborative approach when developing formulas for its customers’ needs. The company also works closely with its customers throughout every step of the process in order to ensure satisfaction with the end results.

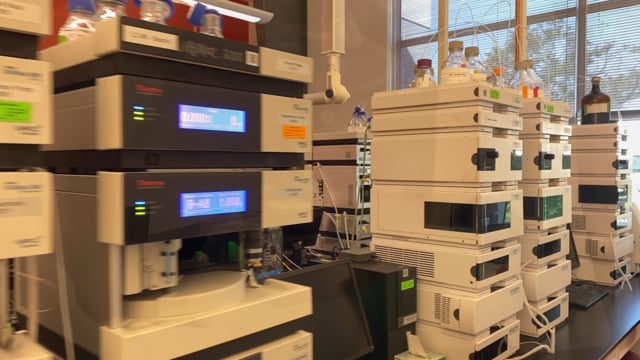

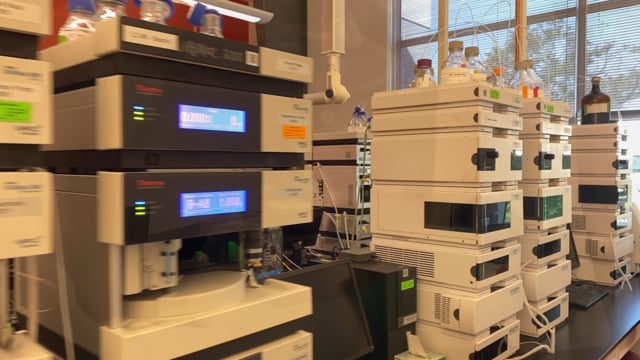

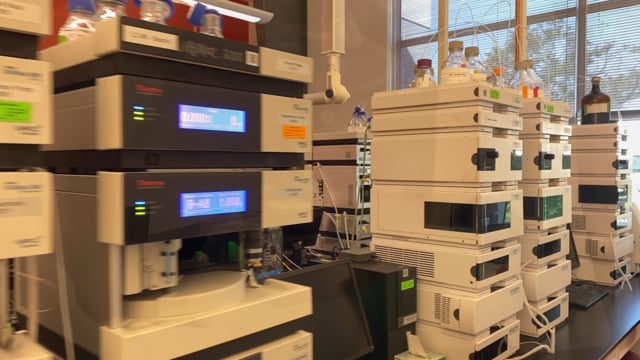

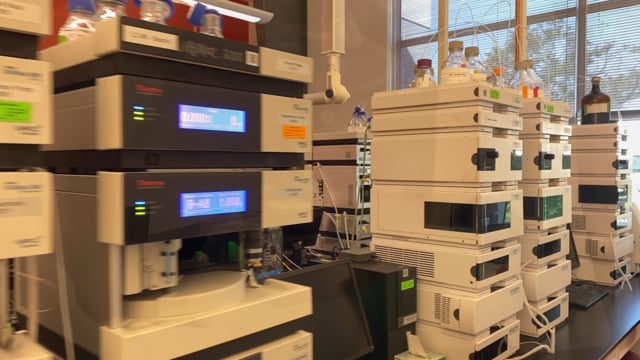

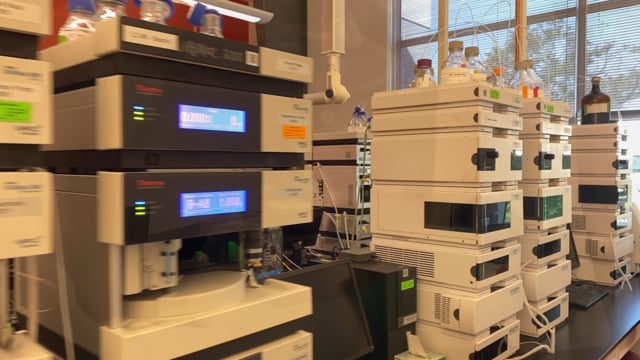

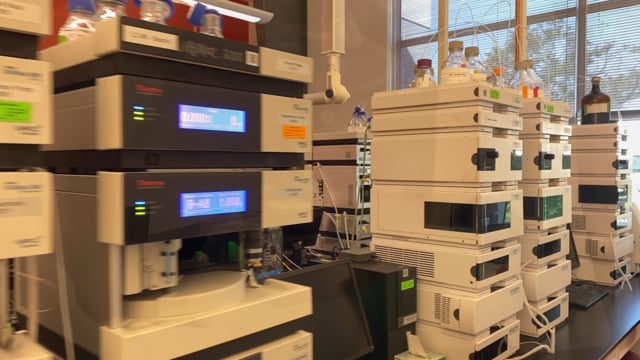

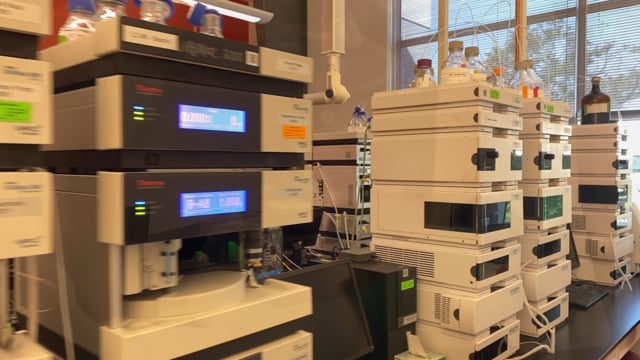

In addition to offering quality services that meet customer needs at competitive rates Dow Development Labs is known for its expertise in formulating solutions for difficult applications such as those involving active ingredients or allergens sensitive formulations like those used in topical creams or gels intended for sensitive skin types . The availability of specialized resources such as sophisticated analytical labs allows them to develop methods specifically tailored towards each customer’s unique product formulation requirements . Furthermore , they take into account both regulatory compliance requirements , such as FDA guidelines , Good Manufacturing Practice (GMP) standards , International Conference on Harmonization (ICH) guidelines – ensuring quality control across different global regions – while also being mindful of cost constraints .

Overall , partnering with Dow Development Labs helps ensure customers get access to top-notch research & development capabilities combined with expert consultation services geared towards improving stability & performance outcome . Plus , their extensive experience working within different regulatory frameworks across multiple countries provides unique insights into how best tackle any potential issues related to formulation & delivery systems before they become problematic during production scale up . As such , Dow Development Labs offers a great opportunity for any business looking into enhancing stability & performance outcomes from their topical products without compromising on cost efficiency or regulatory compliance . To learn more about how Dow Development Labs can help achieve your desired goals contact us today!

Dec 11, 2023 | Articles

As pharmaceutical companies seek to develop effective topical formulations, they must consider a number of advanced strategies that go beyond basic product design. Utilizing the services of an experienced lab such as Dow Development Labs can be a valuable asset in creating the best possible products for their patients.

The first step in creating an effective formulation is to determine the desired characteristics of the product. This includes not only its physical properties such as viscosity, but also its biological and therapeutic effects. It is important to consider how these parameters might interact with one another and what methods should be used to achieve them. Additionally, research into current trends and market needs can prove helpful in designing a formulation that meets customer expectations.

Once the desired characteristics are identified, it’s time to select the ingredients that will best meet those objectives while minimizing potential risks associated with any active ingredients used in the formulation. The selection process requires careful consideration of key parameters such as solubility, compatibility with other components, stability over time, and potential toxicity or irritation issues among others. An experienced laboratory like Dow Development Labs can help navigate this process by providing access to their extensive library of existing formulations and ingredients which can save considerable time and resources while still allowing room for innovation and customization.

Formulation optimization is necessary for achieving maximum efficacy from active ingredients while minimizing side effects. This involves testing various combinations of components under different conditions using sophisticated equipment, something which an experienced lab provides access to along with expert advice on how best to proceed based on their findings. It is also important to evaluate whether any changes have had unintended consequences on other components or if there are any significant differences between batches due to manufacturing variation so that corrective action can be taken if necessary. Once again, having access to professionals who understand these complexities can greatly improve outcomes when developing a new product formulation compared with attempting it alone without specialized resources or expertise at hand.

Finally, once an effective topical formulation has been developed it needs adequate packaging for storage and delivery purposes while meeting all relevant regulatory requirements in terms of labeling accuracy and safety measures during handling/transportation/dispensing processes etc.. This may involve using special materials or techniques which require specialized knowledge and experience; once again Dow Development Labs provides access not only to state-of-the-art packaging solutions but also expert consultation on what would work best for each specific product application taking into account factors such as cost effectiveness etc..

In conclusion, developing an effective topical formulation involves more than just basic product design; utilizing advanced strategies such as ingredient selection & optimization testing under various conditions along with appropriate packaging & labeling are essential steps in achieving successful outcomes when creating new products for patient use. By partnering with Dow Development Labs pharmaceutical companies have access not only to specialized equipment/facilities but also experienced personnel who understand these complexities making them invaluable assets when developing topical formulations quickly & effectively – something which could prove invaluable when meeting customer demands or staying ahead of competitors in today’s ever-evolving market landscape!

Dec 4, 2023 | Articles

Navigating the complex landscape of regulatory requirements for topical pharmaceuticals can seem daunting, but with the right knowledge and guidance, any development process can become manageable. It is essential to partner with a laboratory that has expertise in topicals and can guide you every step of the way.

The first step in developing a topical is to understand the regulatory requirements. The FDA regulates topical pharmaceuticals under its over-the-counter monograph system. This system consists of monographs that define acceptable ingredients, strength, dosage form, and labeling for various types of products. In addition to FDA regulations, there may be other state or local regulations that apply as well as Good Manufacturing Practices (GMP) guidelines which must be followed for all drug products.

When developing a topical product it is essential to understand what type of testing will be required throughout the process in order to ensure safety and efficacy. This includes preclinical studies such as skin irritation studies as well as clinical studies such as those required by FDA for certain products. It is also important to consider how the product will be packaged and labeled before beginning formulation work so that it meets all regulatory requirements from the start.

Formulation work should also take into consideration any potential stability or compatibility issues with ingredients that may arise during storage or use. Knowing what type of testing needs to be done prior to release can help avoid costly delays due to formulation changes during development when stability issues are discovered later on in development process. It is important to partner with an experienced laboratory who understands these complexities and can help guide you through each step without compromising safety or efficacy of your product.

At Dow Development Labs we specialize in formulating quality topical products while ensuring compliance with current good manufacturing practices (cGMP). Our experienced team has developed hundreds of successful formulations for both over-the-counter (OTC) products and prescription drugs (Rx). We provide full service support from concept through method development, packaging/labeling design, stability testing, analytical method validation and more – so our clients have peace of mind knowing their product will meet all applicable standards before it goes out into market place.

We understand navigating regulatory requirements for topical pharmaceuticals can be overwhelming but Dow Development Labs stands ready to help you ensure your product meets all necessary regulations while maintaining quality and efficacy. Contact us today so we can discuss how we can best serve you during your project!

Nov 27, 2023 | Articles

Bringing a topical pharmaceutical product to market is no small feat. It requires a high level of regulatory knowledge, compliance, and research in order to ensure safety and efficacy. Navigating this complex process can be daunting for companies new to the pharmaceutical industry, or those who lack the specialized resources and experience needed. Outsourcing development services such as formula development, method development, packaging, labelling and product testing to a trusted laboratory partner can make all the difference in bringing your topical pharmaceutical product to market.

The first step in navigating the regulatory path is determining which regulatory body will have jurisdiction over the product. This is typically done by mapping out all global markets that you plan to distribute your product in. Each country will have different regulations based on its own governing bodies that must be taken into account when developing your product. Once you understand which regulators will oversee your process, you’ll need to develop plans for compliance with each one of them in order to gain approval for distribution of your product into that market.

Next comes the research and development phase of bringing a topical pharmaceutical product to market. This includes developing formulas that meet specifications according to each country’s regulation requirements while also being cost effective and safe for consumers. Product testing is essential during this stage as it ensures the safety of consumers once they start using it while also verifying its effectiveness in delivering desired results such as relief from certain conditions or symptoms related to skin care products or pain relief from ointments etc.. All these tests must be performed on samples taken from each batch produced prior release into any given market place as required by law enforcement agencies such as FDA (Food & Drug Administration) in United States or other similar agencies around world . In addition , Packaging & Labelling plays very vital role during this phase , since it not only protects from spoilage but also provides necessary information required by end user about contents & storage condition etc..

For companies looking for an experienced laboratory partner who can help them navigate this complex process with confidence, Dow Development Labs offers comprehensive services covering Formula Development , Method Development , Packaging/Labelling & Product Testing . With over two decades of experience providing quality assurance solutions across industries including pharmaceuticals, Dow Development Labs has earned trust and respect amongst their clients due their commitment towards delivering high quality services at competitive prices . As part of our offering we provide comprehensive guidance throughout all stages of regulatory approval process so that our clients can benefit from our extensive expertise without having worry about complexities involved during entire journey .

When looking for an outsourcing partner for formula development, method development packaging/labelling and/or product testing services related to topical pharmaceutical products , look no further than Dow Development Labs . We create custom solutions tailored specifically for your needs while helping you adhere to all applicable regulations along way with complete confidence ! Contact us today learn more about how we can help bring your topical pharmaceutical dream come true !

Nov 20, 2023 | Articles

Advances in the development of topical pharmaceutical products have been made possible by the introduction of new and improved technology. Nowadays, pharmaceutical companies are able to create more effective products with greater safety and accuracy than ever before. This is especially true for topical products, which require precise formulation and packaging in order to be distributed safely and effectively.

In order to create a successful product that meets all the necessary requirements, it is important for companies to make use of the latest technological advances. For example, by utilizing advanced analytics software, they can monitor their processes more closely and ensure that they are meeting all safety regulations throughout the entire development process. This kind of software can also help them track each step of their product’s development journey, allowing them to identify potential areas where improvements can be made quickly and efficiently.

Furthermore, advanced technologies such as 3D printing have revolutionized how many companies develop their topical products. By using 3D printing techniques during formulation development or prototyping stages, they are able to significantly reduce their time-to-market while maintaining high levels of accuracy in their results. Additionally, this technology can also be used for creating custom packaging solutions that will keep their products safe during transit and storage conditions.

In addition to these technological advancements that make it easier for companies to effectively develop their topical pharmaceuticals, there are other advantages as well: outsourcing certain processes or services like method development, packaging or product testing can help them reduce costs while still ensuring that everything is done correctly and according to industry standards. By partnering with a top laboratory like Dow Development Labs who specialize in providing these services for pharmaceutical companies across the globe can help you achieve your goals faster without compromising on quality or safety standards.

Overall, advances in technology have made it much easier for today’s pharmaceutical companies when it comes to developing effective topical products that meet all regulatory requirements while cutting down on costs at the same time. By utilizing modern tools such as analytics software or 3D printing techniques during formulation development stages as well as outsourcing certain services like method development or product testing from a top lab like Dow Development Labs—companies can now create better quality products at a faster rate than ever before with minimal risk involved along the way. If you’re looking for an experienced partner who understands your needs when it comes to creating top-tier topical pharmaceuticals then look no further than Dow Development Labs – contact us today so we can start working together!