Nov 13, 2023 | Articles

When pharmaceutical companies and scientific development labs are looking to partner with a laboratory for formula development, method development, packaging, labelling, and/or product testing, it’s important to take into consideration the benefits of working with a professional topical pharmaceutical product development company. The right laboratory can provide a number of advantages over other alternatives.

One of the greatest advantages of partnering with a professional topical pharmaceutical product development company is the expert knowledge and experience they offer. Professional laboratories have years of experience in developing formulas for topical products that can help ensure that your product is safe and effective for consumers. They also understand the regulatory requirements in different countries so you can rest assured that your products will meet all applicable standards.

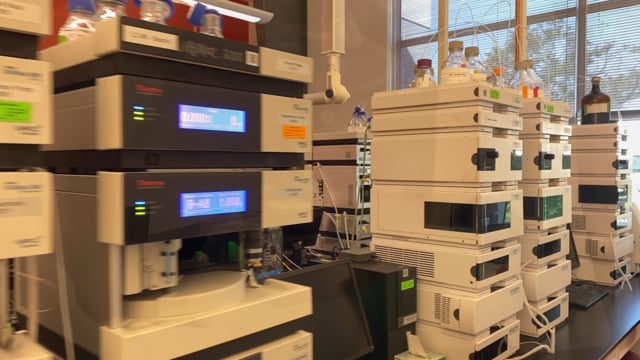

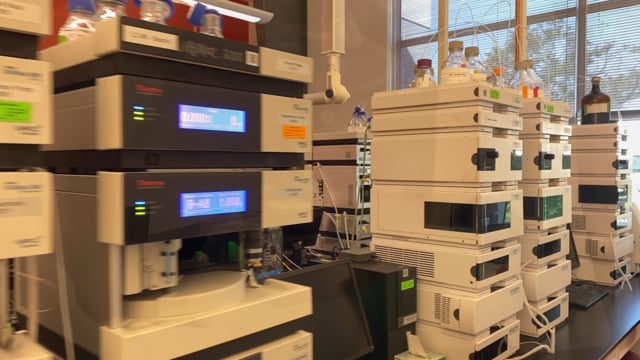

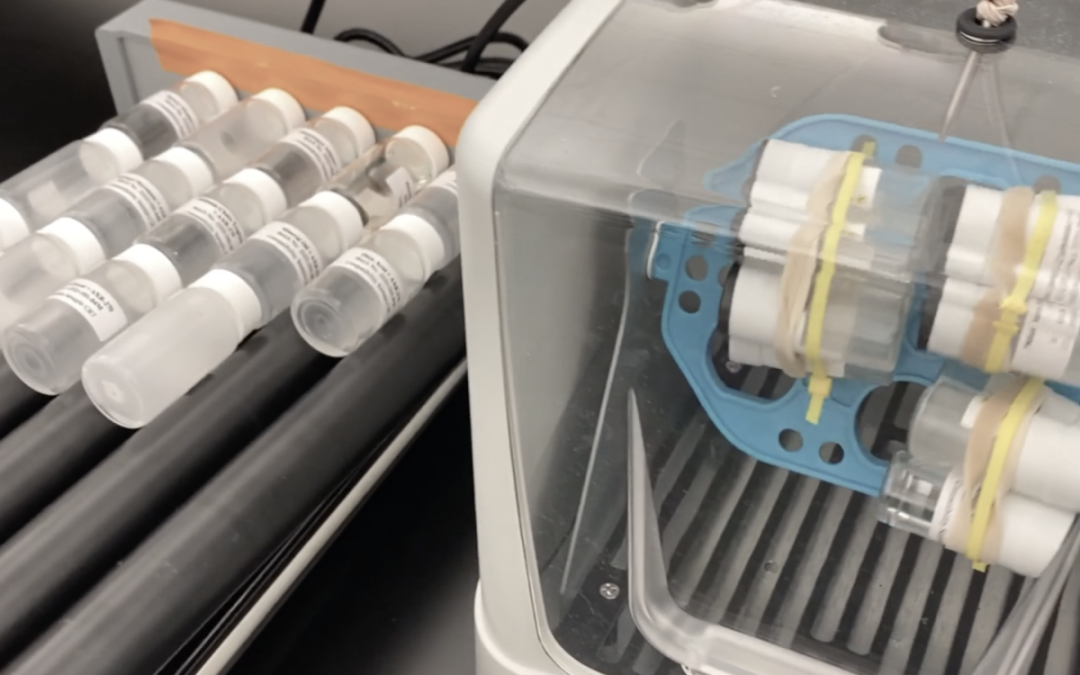

Another benefit of working with a professional topical pharmaceutical product development company is their access to state-of-the-art equipment. Many laboratories are equipped with advanced technology such as high-performance liquid chromatography (HPLC) and gas chromatography (GC) which allows them to accurately analyze ingredients at each stage of formulation and production. This ensures that your products contains only safe ingredients while also meeting label claims such as efficacy or stability.

A third advantage offered by some professional laboratories is specialized services such as esthetic evaluation or consumer testing which may be required when creating certain types of products such as cosmetics or sunscreens. These services can help ensure you create optimal formulations that will both please consumers and meet regulatory requirements.

In addition to providing expertise and specialized services, many professional laboratories offer additional benefits such as cost savings due to bulk purchasing power, faster turnaround times due to experienced staff being able to work on multiple projects simultaneously, guaranteed confidentiality through non-disclosure agreements (NDAs), flexible payment terms tailored to your budget, and access to free consultations on how best to achieve desired outcomes from formulation changes or packaging adjustments.

By partnering with an experienced professional laboratory you will be able to trust in their expertise while taking advantage of all the benefits they offer including expert knowledge, state-of-the art equipment, specialized services when needed, cost savings through bulk purchasing power, faster turnaround times due higher productivity rates among staff members; guaranteed confidentiality via NDAs; flexible payment terms; free consultations on how best achieve desired outcomes from formulation changes or packaging adjustments; etc.. All these factors make partnering with an experienced topical pharmaceutical product development company an ideal choice for any business looking for reliable partners in developing top quality formulas and products within budgeted timelines. Working with Dow Development Labs can give you peace of mind knowing that they have years’ worth of experience providing reliable service tailored specifically for those in need of top quality formula developments for topical products––contact us today if you’re ready to take your business further!

Nov 8, 2023 | Articles

When it comes to developing topical pharmaceuticals, formulating and delivering them in a way that ensures safety and efficacy is of utmost importance. It is therefore essential to partner with an experienced lab specialising in product development, such as Dow Development Labs.

The aim of formulation and delivery systems for topical pharmaceuticals is to ensure maximum safety and efficacy while avoiding potential skin irritation or other adverse reactions. In order for this to be achieved, the right combination of ingredients needs to be carefully selected along with the right delivery system. This includes examining the active ingredients, excipients (inactive components), physical properties, composition, dosage forms and stability parameters.

It is also important to consider how the drug will react with any potential contaminants on the skin surface prior to being absorbed into the body. Contaminants can include bacteria, fungi or other microorganisms that may alter drug performance if not addressed properly during formulation development. Additionally, understanding how different pH levels will affect delivery systems such as gels or creams is also necessary in order to ensure safety and efficacy of topical pharmaceuticals.

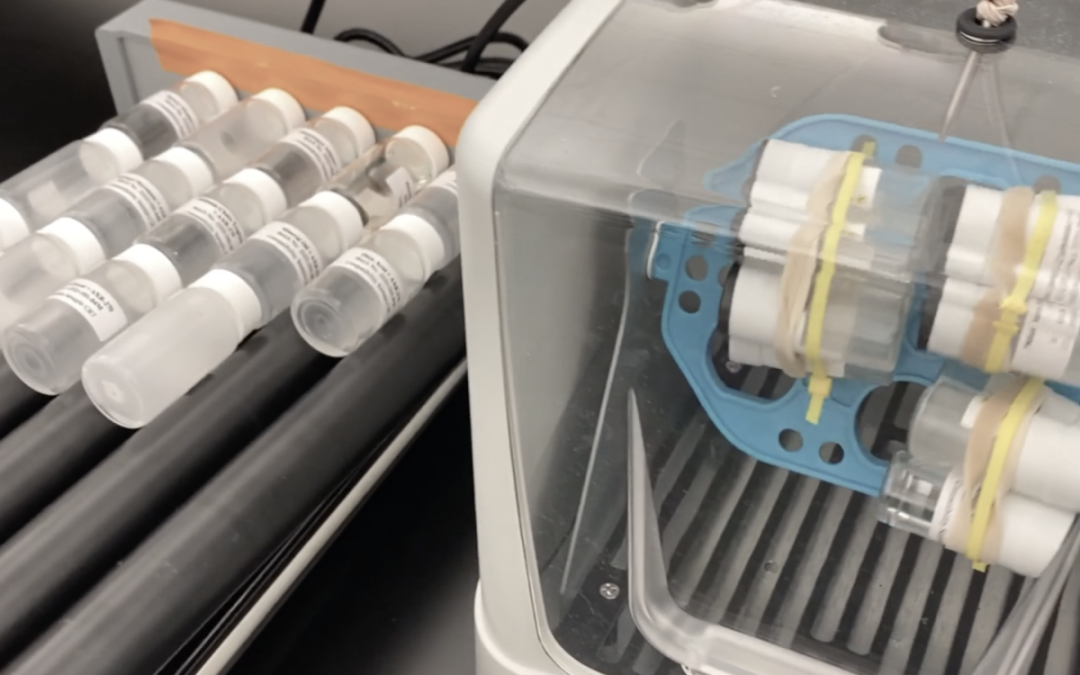

Formulation development should also consider how quickly drugs are released from a delivery system following application onto the skin surface as this will impact overall safety and efficacy. Finally, packaging materials should also be evaluated as they need to provide appropriate protection against environmental contamination which could potentially alter product performance over time.

At Dow Development Labs we have extensive experience working with clients across various industries when it comes to formula development for topical pharmaceuticals. Our team works collaboratively with our clients throughout all stages of product development from concept through design validation stages ensuring maximum safety and efficacy while helping them launch successful products that meet their desired specifications at an accelerated timeline compared to traditional methods used by many laboratories today.

Our team consists of highly experienced professionals who understand what it takes to develop safe and effective products that meet stringent regulatory standards when it comes to manufacturing processes including packaging/labelling protocols as well as quality control testing procedures required by international regulatory bodies such as FDA (US Food & Drug Administration) or EMA (European Medicines Agency). We use our extensive expertise in method development along with state-of-the-art equipment/technologies enabling us offer customised solutions meeting each client’s individual needs while minimising costs associated with traditional product development methods employed by other laboratories today.

At Dow Development Labs we understand that every client has unique needs when it comes developing their own unique formulations so we are committed providing comprehensive support throughout each stage of product development – from concept through validation – ensuring maximum safety and efficacy without compromising on quality standards set forth by regulatory bodies worldwide while helping clients launch successful products at an accelerated timeline compared traditional methods employed by many laboratories today.. If you’re looking for an experienced laboratory partner for formulating safe and effective products then contact Dow Development Labs today!

Oct 2, 2023 | Articles

In the dynamic field of pharmaceuticals, topical formulation development companies emerge as architects designing effective and safe skincare solutions. These entities are central to developing innovative products that address a myriad of skin conditions, offering relief and therapeutic benefits to users worldwide.

The Science of Crafting Formulations

Topical formulation development companies specialize in creating various product formulations like creams, ointresses, gels, and lotions. The process begins with a scientific approach to develop formulations designed for optimal therapeutic effects while ensuring product stability and patient-friendly characteristics. Each ingredient, whether active pharmaceutical ingredient (API) or excipient, is carefully chosen and balanced to meet specific therapeutic and aesthetic requirements.

A Landscape of Diverse Applications

Addressing a wide range of therapeutic indications, from dermatological concerns to pain management, wound healing, and beyond, these companies craft products tailored to specific applications. With a deep understanding of the unique challenges associated with different skin conditions, these experts develop formulations that not only provide relief but also promote skin health and wellness.

Navigating Regulatory Complexity

One of the significant challenges in the pharmaceutical industry is adhering to the stringent regulations set by healthcare authorities. Topical formulation development companies are adept at navigating through these regulatory complexities. They ensure that every product developed aligns with the set standards, facilitating smooth approval processes and ensuring the final products are safe for consumers.

Ensuring Quality and Safety

Quality assurance is non-negotiable in the realm of topical formulations. Companies specializing in this field implement rigorous testing protocols and quality control measures throughout the development process. This meticulous approach guarantees that the final products meet the highest standards of quality, safety, and efficacy.

Supporting the Journey from Concept to Market

From the initial conceptualization of a product to its development, testing, and final approval, topical formulation development companies support pharmaceutical brands in bringing their visions to life. These entities provide a comprehensive suite of services that encompass the entire product development lifecycle, serving as invaluable partners in introducing innovative and reliable skincare solutions to the market.

Conclusion: Steering Innovation in Skincare Formulations

Topical formulation development companies play a pivotal role in steering the innovation and development of groundbreaking skincare solutions. With their expertise, commitment to quality, and understanding of the regulatory landscape, they contribute immensely to offering products that improve the quality of life for users across the globe.

Organizations like Dow Development Laboratories stand out as leaders in this field, demonstrating a relentless pursuit of excellence and innovation in developing topical formulations. Through their concerted efforts, these companies continue to push the boundaries of what’s possible in skincare, offering hope and relief to millions through their state-of-the-art products.

Oct 2, 2023 | Articles

In the ever-evolving pharmaceutical landscape, Contract Development and Manufacturing Organizations (CDMOs) specializing in topical products stand as invaluable partners for companies seeking to develop and manufacture cutting-edge skin care solutions.

The Pivotal Role of Topical CDMOs

Topical CDMOs play a critical role by offering end-to-end services, from initial product conception to the final steps of manufacturing and packaging. These organizations possess the specialized knowledge and facilities required to develop a wide range of topical formulations, including creams, lotions, ointments, gels, and patches, addressing various skin conditions and promoting skin health.

Embarking on a Collaborative Journey

Engaging with a topical CDMO allows pharmaceutical companies to embark on a collaborative journey where innovation meets technical expertise. The partnership begins with an in-depth discussion and understanding of the product concept and intended therapeutic effects, forming the foundation for the subsequent stages of development and manufacturing.

Expertise in Formulation Development

A significant aspect of a topical CDMO’s expertise lies in the domain of formulation development. The organization’s scientists are skilled in crafting formulations that not only contain the right proportions of active pharmaceutical ingredients (API) and excipients but also offer stability, efficacy, and patient-friendly attributes. Through rigorous testing and analysis, they ensure that the formulated products are safe for use and compliant with regulatory standards.

Precision in Manufacturing Processes

Once the prototype is developed and tested, the process transitions into the manufacturing phase. Topical CDMOs are equipped with advanced manufacturing facilities that can handle various batch sizes, maintaining the integrity and quality of the product throughout the production cycle. The manufacturing process is meticulously monitored to adhere to Good Manufacturing Practices (GMP), ensuring the final product meets the highest standards of quality and safety.

Quality Assurance and Regulatory Compliance

Quality assurance is deeply embedded in the operations of topical CDMOs. Each product undergoes stringent testing and validation to ensure it aligns with the predefined quality parameters. Furthermore, these organizations are well-versed in navigating the complex regulatory environment, ensuring that the products manufactured comply with the rules and guidelines set by health authorities.

Conclusion: A Beacon of Excellence in Topical Solutions

Topical CDMOs serve as beacons of excellence, guiding pharmaceutical companies through the intricate process of topical product development and manufacturing. With their depth of expertise and commitment to quality, they are instrumental in bringing innovative, effective, and safe skin care solutions to the market.

Organizations like Dow Development Laboratories epitomize the essence of a proficient topical CDMO, offering unparalleled services that encompass the entire lifecycle of topical pharmaceutical products. Through their dedicated efforts and unrelenting pursuit of excellence, topical CDMOs continue to contribute significantly to advancing skin care science and improving the lives of patients worldwide.

Oct 2, 2023 | Articles

In the intricate tapestry of pharmaceutical sciences, topical pharmaceutical method development is a segment that holds paramount importance. This meticulous process lays the groundwork for creating topical solutions that are potent, safe, and dependable, ensuring a positive impact on patient health and wellbeing.

Understanding Method Development in Pharmaceuticals

Topical pharmaceutical method development is an intensive, scientific approach used to establish reliable testing and analytical procedures for topical drugs. These methods become the standard for evaluating the quality, safety, and efficacy of the product from the manufacturing line to the shelf.

Initiating the Method Development Process

The inception of the topical pharmaceutical method development process is characterized by identifying and understanding the characteristics of the active pharmaceutical ingredient (API) within a topical formulation. With an intimate knowledge of the API’s chemical and physical properties, scientists can then begin crafting testing methods that are precise and appropriate.

Investigating Compatibility and Stability

A cornerstone of method development is ensuring the stability and compatibility of the API with various excipients found in the formulation. Through systematic studies, scientists explore how the API interacts with other components under different conditions. This exploration is fundamental for developing methods that accurately reflect the product’s real-world stability and efficacy.

Developing Analytical Techniques

With a foundational understanding established, the focus shifts to developing and refining analytical techniques. These techniques are crucial for accurately quantifying the API and its related substances, preservatives, and other critical components within the formulation. The process involves utilizing advanced equipment and technologies, such as High-Performance Liquid Chromatography (HPLC), to ensure precise and reliable analysis.

Ensuring Regulatory Compliance

Topical pharmaceutical method development also involves creating methods that comply with regulatory standards. Each testing procedure is meticulously developed to meet the stringent requirements set by healthcare regulatory bodies, ensuring that the topical products pass through all the necessary checks and balances before reaching consumers.

Setting the Stage for Quality Assurance

The methods developed during this process become the bedrock for quality assurance in topical pharmaceutical products. They serve as the guiding protocols for testing and validation during manufacturing, ensuring that each batch of the product aligns with the expected levels of quality and efficacy.

Method Development as a Pillar of Excellence

Topical pharmaceutical method development is a disciplined, scientific process that plays a pivotal role in bringing safe and effective topical treatments to the market. With a carefully crafted set of testing methods, manufacturers can consistently produce products that meet and exceed quality standards, ultimately contributing to the health and safety of patients around the globe.

Institutions like Dow Development Laboratories are at the forefront of this endeavor, employing their expertise and cutting-edge technology to advance the field of topical pharmaceutical method development. Through their commitment to excellence and innovation, the future of topically applied pharmaceuticals is bright, promising enhanced treatment options and improved patient outcomes in the years to come.

Oct 2, 2023 | Articles

In the labyrinthine corridors of healthcare solutions, the segment of topical pharmaceutical drug product manufacturing gleams with immense significance. This process is the cornerstone behind the production of products that patients around the world rely on for diverse skin-related conditions and diseases.

Initiating the Manufacturing Process

Topical pharmaceutical drug product manufacturing is initiated after the comprehensive development phase culminates. Here, the meticulously designed formulations, intended to alleviate specific skin conditions or facilitate general skin health, transition from the prototype stage to actual production.

Precision in Ingredient Mixing

The manufacturing process demands precision. The first step involves the accurate measuring and mixing of the active pharmaceutical ingredient (API) with selected excipients. Every ingredient, from the primary API to the smallest stabilizer, is weighed and mixed with exactness to create a batch that mirrors the approved prototype in efficacy and safety.

Compatibility and Stability Testing

Compatibility testing continues even during the manufacturing stage to ensure that the API remains stable and effective within the formulation during the scale-up process from lab-sized batches to commercial-sized ones. Stability is not only crucial for the product’s immediate use but also paramount for its shelf life, maintaining the product’s integrity over time.

Efficient and Safe Packaging

After the products are formulated and tested for stability and compatibility, they are prepared for packaging. Packaging in topical pharmaceutical drug product manufacturing isn’t merely about containment; it’s also about preservation and safety. Whether it’s creams filled in tubes or solutions in bottles, the packaging is selected not only to protect the product but also to facilitate easy application by the end-users.

Quality Control: The Unseen Guardian

Every stage of the manufacturing process is overseen by stringent quality control measures. These measures are in place to ensure that the final product aligns with the set standards of quality, efficacy, and safety. Through various tests and checks, quality control specialists ensure that each product leaving the manufacturing line is fit for use.

Regulatory Adherence and Compliance

Topical pharmaceutical drug product manufacturing is tightly regulated. Every batch produced must adhere to the guidelines set by regulatory bodies. From the sourcing of ingredients to the final packaging, each step complies with the standards established by authorities, ensuring the products reaching consumers are safe and effective.

Conclusion: Crafting Solutions for Skin Health

The sphere of topical pharmaceutical drug product manufacturing is intricate, requiring a ballet of precision, quality assurance, and compliance. It’s an arena where science and logistics merge seamlessly to produce remedies that support and enhance the health of skin across different ages and conditions.

As we continue to witness advancements in technology and pharmaceutical sciences, the sector of topical drug product manufacturing is poised for innovative leaps. These future strides will undoubtedly bring forth products that are more effective, safer, and tailored to meet the diverse needs of global patients, contributing significantly to the landscape of skincare and treatment.