Oct 2, 2023 | Articles

In the dynamic realm of healthcare and pharmaceuticals, topical pharmaceutical product development stands out as a key area that is both challenging and essential. It refers to the sophisticated process of creating medicated products that can be applied directly to the skin for localized or systemic effect.

Embarking on Development Journey

The journey of topical pharmaceutical product development begins with a well-defined concept anchored on addressing specific skin-related needs or conditions. Recognizing the need is critical, as it sets the stage for all subsequent steps, from formulation design to final product testing and release.

Crafting Formulations with Precision

Once a need is identified, the focus shifts to the formulation process. The active pharmaceutical ingredient (API), serving as the cornerstone of the therapeutic effect, must be meticulously selected. However, the formulation’s success doesn’t solely depend on the API. It is a symphony of various components, each playing a crucial role. Excipients, the non-active ingredients, are incorporated to aid in the delivery, stability, and usability of the product.

In topical pharmaceutical product development, understanding the interactions between the API and excipients is paramount. Scientists perform solubility and compatibility studies to ensure that the chosen ingredients can work synergistically without compromising the product’s stability or effectiveness.

Evolving from Prototypes to Final Products

With a stable and effective formula in hand, the development process moves forward to prototype creation and testing. Various prototypes are designed, and each undergoes rigorous evaluation to assess their stability, efficacy, and safety. This phase might involve accelerated stability studies, in vitro skin penetration studies, and other assessments to select the best-performing prototype.

Ensuring Compliance and Safety

The selected lead formulation then progresses to IND-enabling studies, following Good Laboratory Practices (GLP). These crucial studies provide the necessary data to support the Investigational New Drug (IND) application, a prerequisite for initiating clinical trials. This phase of topical pharmaceutical product development is crucial, as it ensures the product’s safety and efficacy before it is introduced to patients.

Navigating a Complex Development Landscape

Topical pharmaceutical product development is an intricate dance between science and art, where precision, creativity, and deep understanding of chemistry, biology, and pharmacology converge. It’s a continuous endeavor aimed at introducing innovative, effective, and safe products that address various skin conditions and improve patients’ lives.

Through meticulous research and development, experts in the field, like those at Dow Development Laboratories, continue to push the boundaries of what’s possible in topical pharmaceutical product development, promising a future of advanced and sophisticated solutions for skincare and treatment.

Oct 2, 2023 | Articles

Topical pharmaceutical product formulation is a meticulous process that combines science and expertise to create products designed for skin application. These products, including creams, ointments, gels, and others, are integral in treating various skin conditions and diseases.

The First Step in Topical Pharmaceutical Product Formulation

Every journey begins with a single step, and in topical pharmaceutical product formulation, it starts with selecting the appropriate active pharmaceutical ingredient (API). The API is the heart of the formulation, chosen for its therapeutic effect on specific skin issues. However, an API cannot work alone; it needs a team of supporting ingredients, known as excipients, to enhance its stability, solubility, and overall performance.

Creating a Stable and Effective Mixture

A crucial aspect of topical pharmaceutical product formulation is ensuring the API and excipients work harmoniously. Scientists conduct extensive solubility studies to understand the API’s behavior in various solvents. The goal is to identify a solvent that can dissolve the maximum amount of API, creating a solution that can be efficiently absorbed by the skin.

Compatibility studies are equally important, ensuring that the chosen excipients don’t negatively interact with the API, maintaining the stability of the final product. With this foundation, prototype formulations are designed and developed, incorporating various other ingredients like preservatives, antioxidants, and emulsifiers.

Screening and Selecting the Optimal Formulation

In topical pharmaceutical product formulation, once prototypes are created, they undergo rigorous testing. Accelerated stability studies are conducted to compare the stability of different prototypes under various conditions. In vitro skin penetration studies might also be performed to understand how well the API can traverse through the skin layers from different formulations.

Based on these screenings, a lead formulation is selected for further development. This selected prototype then progresses to IND-enabling studies, adhering to Good Laboratory Practices (GLP). These studies provide crucial data supporting the Investigational New Drug (IND) application, a necessary step before clinical trials commence.

The Art and Science of Formulation

Topical pharmaceutical product formulation is a field where science meets art. It requires not only a deep understanding of various scientific principles but also the creativity and innovation to develop products that are effective, stable, and patient-friendly. With continuous research and development in this area, the future promises more advanced and efficient topical pharmaceutical products, enhancing the treatment options available for various skin conditions and improving the quality of life for patients worldwide.

Sep 12, 2023 | Articles

In an era where healthcare innovation is at the forefront of global progress, organizations like Dow Development Labs (DDL) have etched their presence as leaders in their niche. Their commitment to the development of topical drug products has significantly influenced how the industry perceives and approaches this specialized segment of pharmaceuticals.

A Brief Glimpse into DDL’s Genesis

Dow Development Laboratories, LLC, better known as DDL, is not just another entity in the vast pharmaceutical landscape. Functioning as the topical drug development arm of Symbio, LLC, DDL combines the rigor of scientific investigation with clinical expertise. Its ties to Symbio, a clinical research powerhouse, solidify its status as an entity deeply rooted in both research and practical applications.

The DDL Facility: A Hub of Innovation

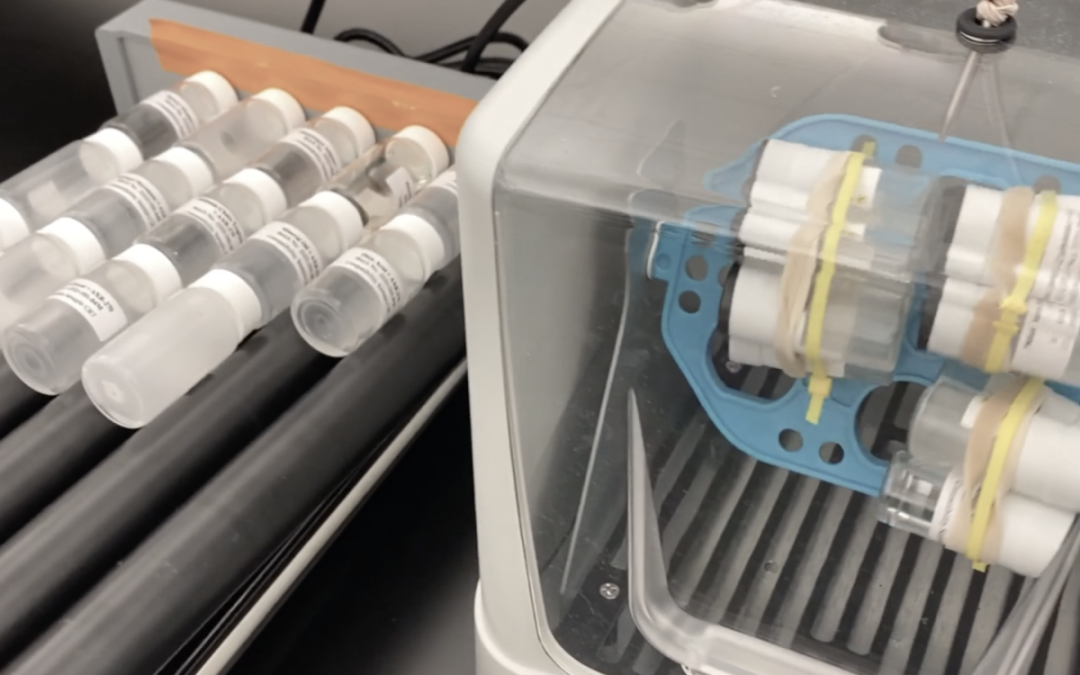

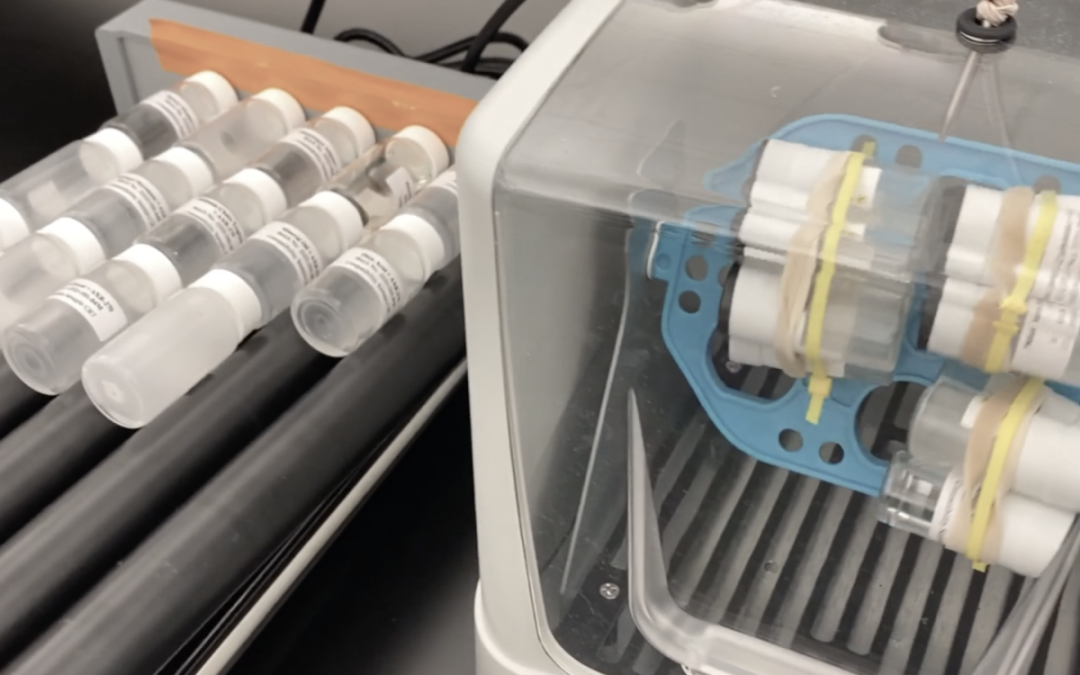

Nestled in Northern California, DDL boasts a sprawling 23,000 square foot cGMP compliant facility. Designed keeping in mind the unique challenges and nuances of topical drug development, this facility serves as a nerve center for various processes, from formulation to testing and packaging. Such a comprehensive setup facilitates a seamless transition of drug products through the various stages of development, ensuring efficiency and quality at each step.

A Spectrum of Expertise

What sets DDL apart is not just its infrastructure but the team behind its operations. With decades of cumulative experience, DDL’s formulation, analytical, production, quality, and clinical labeling groups possess a unique blend of theoretical knowledge and practical expertise. This cohesive approach allows them to usher products quickly towards regulatory approval while always keeping patient needs at the heart of their endeavors.

DDL’s Service Offerings: A Closer Look

- Formulation Design and Optimization: Crafting a topical drug product is both an art and a science. The balance of active ingredients, carriers, and stabilizers is meticulously studied and optimized for each product.

- Analytical Method Development & Validation: Before a product sees the light of day, it undergoes rigorous testing. DDL’s analytical team devises and validates methods to ensure the safety and efficacy of these products.

- In Vitro Release Testing: How does the drug release from its formulation? This crucial aspect is scrutinized in the labs, ensuring a consistent and effective drug delivery system.

- Stability Studies: Every drug product has to retain its efficacy over time. Stability studies evaluate the shelf life of these products and their resistance to various environmental factors.

- Clinical Supplies Manufacturing and Packaging: DDL’s commitment doesn’t end with development. The labs are equipped to manufacture and package clinical trial materials, ensuring that investigational products are of the highest quality.

- CMC Documentation & Consulting: As with all pharmaceutical endeavors, compliance and documentation are crucial. DDL offers support in this domain, ensuring products are ready from both a scientific and regulatory standpoint.

Embracing Challenges: DDL’s Dedication to Complex Formulations

One of the standout aspects of DDL is its expertise in handling complex formulations. Be it new chemical entities (NCEs) or light-sensitive molecules, the labs have showcased their prowess in managing a vast array of topical products. The challenges posed by the intricate nature of these compounds only bolster DDL’s commitment to innovation.

A Partnership Approach

DDL’s success is not just a result of its internal brilliance but also its collaborative spirit. Whether working with clients to generate randomization codes for clinical studies or accommodating external inputs, DDL’s ethos is deeply rooted in partnership and collaboration.

The Legacy and Future of DDL

Dow Development Labs stands as a testament to what passion, expertise, and collaboration can achieve in the realm of pharmaceuticals. With its patient-centric approach, rigorous scientific methodologies, and a team of dedicated professionals, DDL is not just contributing to the present of topical drug development but is also shaping its future. As healthcare continues to evolve, entities like DDL will undoubtedly lead the charge, ensuring better therapeutic solutions for all.

Aug 22, 2023 | Articles

Aug 22, 2023 | Articles

Our skin, often dubbed the body’s canvas, is a marvel of nature. As our protective shield against environmental challenges and a crucial player in sensory perception, the skin’s health remains paramount. Consequently, the creation of dermatological drug products—those remedies designed specifically for skin maladies—becomes a compelling narrative of innovation, precision, and diligence.

The Nuances of Dermatological Drugs

Unlike general skincare products, dermatological drug products contain medicinal agents tailored to treat specific skin ailments. From combating severe conditions like eczema and psoriasis to addressing common concerns like acne or fungal infections, these products serve a pivotal role in healthcare.

The Genesis of a Dermatological Drug Product

- Conceptualizing the Cure: Any drug’s journey commences with identifying a need. Researchers and dermatologists pinpoint common skin concerns and work collaboratively to outline potential therapeutic agents.

- The Formulation Blueprint: Creating a drug is a blend of art and science. Active ingredients, responsible for therapeutic action, are combined with carriers, stabilizers, and other agents. The goal? A stable, effective, and patient-friendly product.

- Prototyping and Pilot Batches: Before large-scale production, small batches are produced for initial testing. This ensures the formula’s efficacy and safety while enabling tweaks based on feedback.

- Validation and Quality Assurance: Manufacturing plants operate under strict guidelines. Every stage, from ingredient sourcing to the final drug creation, undergoes stringent quality checks to ensure the product’s potency, safety, and stability.

- Sterilization and Preservation: Dermatological drugs, being applied to potentially compromised skin, must be free from contaminants. Employing advanced sterilization techniques ensures these products remain uncontaminated and safe.

- Purposeful Packaging: The container isn’t just about aesthetics. It’s about protection. Whether it’s an ointment in a tube, a lotion in a bottle, or a gel in a pump dispenser, packaging plays a critical role in preserving the drug’s efficacy.

- Distribution and Beyond: Once the drug product is ready, it is sent to pharmacies, hospitals, and clinics. But the journey doesn’t end here. Post-market surveillance ensures any potential issues are quickly identified and rectified.

The Roadblocks on the Path

Creating a dermatological drug product is no cakewalk. Challenges arise at every corner:

- Ingredient Sourcing: The quest for high-quality, consistent ingredients is perpetual.

- Regulatory Hurdles: Every region has its set of regulations. Navigating this labyrinth is crucial for global availability.

- Consumer Demands: As consumers become more knowledgeable, their demands evolve. Natural ingredients, sustainable sourcing, and eco-friendly packaging are just a few of the contemporary concerns manufacturers address.

Behind every dermatological drug product lies an intricate dance of science, perseverance, and an unwavering commitment to enhancing skin health. These products, often taken for granted, embody the relentless spirit of countless professionals, ensuring our skin remains at its healthiest best. As we move forward, innovations in biotechnology and pharmacology promise an even brighter future for dermatological care.

Aug 22, 2023 | Articles