Aug 22, 2023 | Articles

Skin, our body’s largest organ, often serves as the window to our overall health. As the protective barrier against the external environment, it’s imperative that any products designed for it undergo meticulous testing. This is especially true for dermatological drug products, where safety and effectiveness are paramount. This article delves deep into the stages and nuances of dermatological drug product testing, ensuring that what we apply to our skin is nothing short of excellence.

1. The Starting Point: Selection of Active Ingredients

Before any drug hits the test labs, it begins with the selection of active pharmaceutical ingredients (API). The choice of API is based on its therapeutic value in addressing specific skin concerns, be it acne, eczema, or a novel skin condition.

2. Compatibility and Formulation Testing

Once the active ingredients are selected, it’s vital to ensure they are compatible with other ingredients, including preservatives and excipients. This stage verifies that the drug’s consistency, whether cream, gel, or ointment, aligns with its intended purpose and remains stable over time.

3. Microscopic Analysis

A closer look, quite literally. With the help of techniques like light microscopy, researchers can get a detailed view of the drug’s physical structure, ensuring uniform distribution of ingredients and absence of unwanted particles or aggregates.

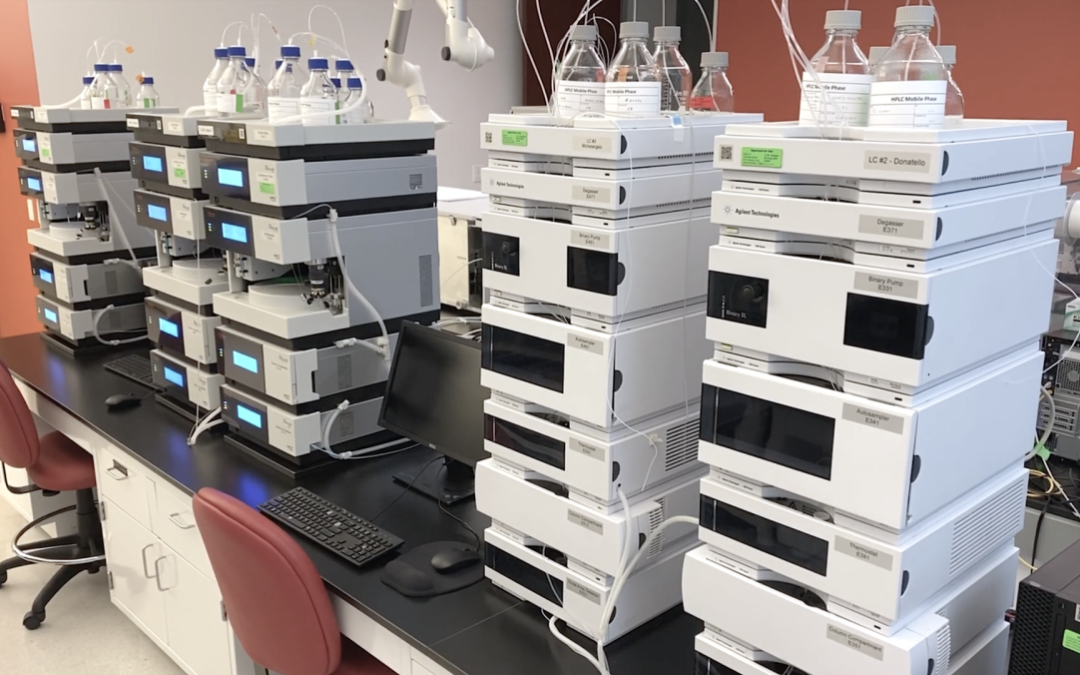

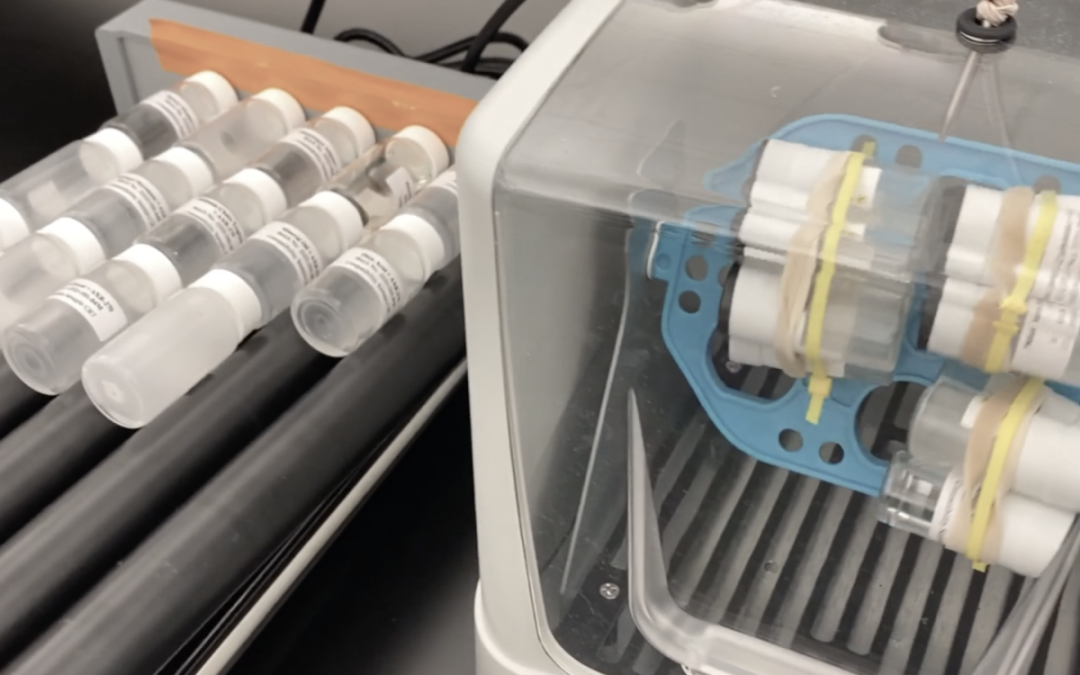

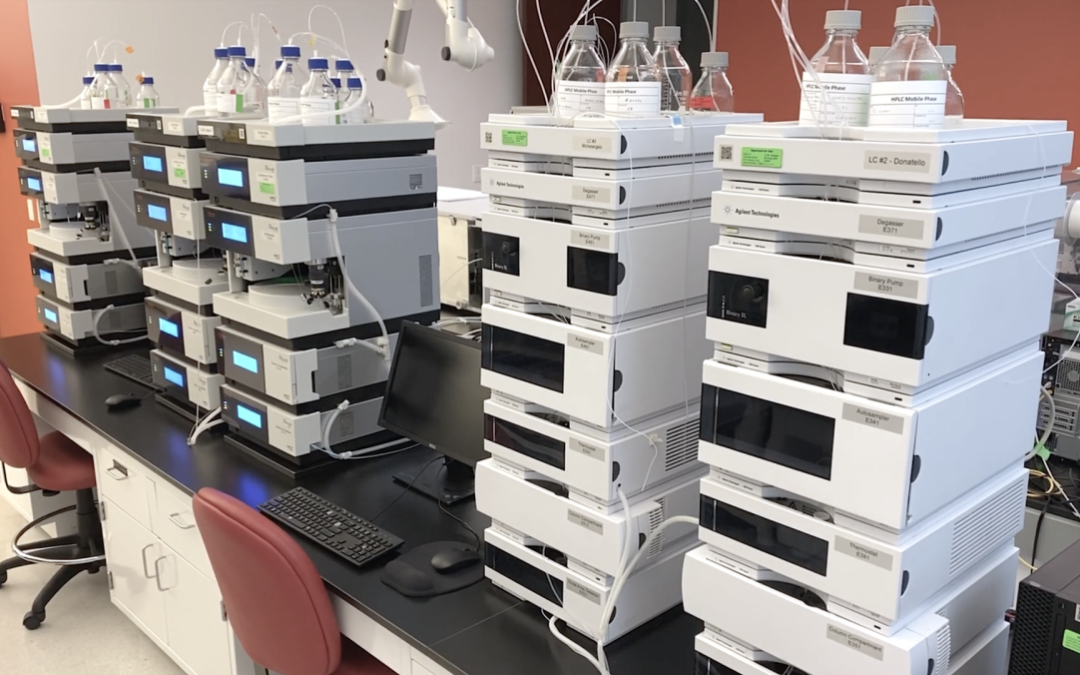

4. Advanced Analytical Techniques

Leading dermatological research institutions employ sophisticated methods to validate the drug’s composition and quality. Techniques like High-Performance Liquid Chromatography (HPLC) ensure the drug contains the right concentration of API, while others like the Thermo Trace 1310 GC can detect any potential impurities.

5. Stability Under Varied Conditions

Dermatological drug products may be exposed to various conditions during their shelf life. Stability testing under varied temperatures and humidities guarantees the product remains potent, safe, and maintains its integrity throughout its intended lifespan.

6. Clinical Trials: The Human Test

While lab tests provide extensive data, the real test of any dermatological drug product is its performance on human skin. Rigorous clinical trials, conducted under strict guidelines, provide insights into the drug’s safety, side effects, and therapeutic efficacy across diverse populations.

7. Real-World Simulations

Dermatological drugs might often be exposed to factors like sunlight, air, or even the constituents of makeup. Real-world simulations test how these products react under such conditions, ensuring they remain safe and effective.

8. Post-Market Surveillance

The testing doesn’t stop once the product is on the shelves. Post-market surveillance ensures that any long-term effects or rare side effects are promptly identified, analyzed, and addressed.

9. Navigating the Regulatory Waters

Every test, every result is meticulously documented and presented to regulatory authorities like the FDA. Meeting their benchmarks is not just about compliance; it’s a testament to the product’s safety and efficacy.

Conclusion

The journey of dermatological drug product testing is a testament to the dedication towards ensuring safety and quality. It’s a rigorous, multi-layered process that intertwines science, technology, and an unwavering commitment to skin health. As consumers, understanding this process reinforces trust in the products we use, ensuring that we’re not only looking our best but are also in the best of health.

Aug 22, 2023 | Articles

Crafting Excellence in Semi-Solid Product Manufacturing

The pharmaceutical world offers a vast array of treatments, but among them, semi-solid preparations hold a unique place. These formulations, which include creams, ointments, gels, and lotions, promise targeted relief and are a preferred choice for many dermatological and therapeutic applications. But how are these products brought to life? Let’s venture into the intricate world of semi-solid product manufacturing.

The Spectrum of Semi-Solid Products

Semi-solids bridge the divide between liquid and solid pharmaceuticals. Their unique texture ensures they are easily spreadable, allowing for consistent drug delivery and a localized effect. This ensures a rapid onset of action, reduced systemic absorption, and often, fewer side effects.

Steps in the Manufacturing Process

- Raw Material Inspection: Every masterpiece begins with choosing the right materials. In semi-solid manufacturing, raw materials, including the active pharmaceutical ingredient (API) and various excipients, undergo stringent quality checks to ensure purity and potency.

- Blending and Mixing: The heart of the process. Here, the ingredients are blended to achieve a uniform mixture. Advanced equipment ensures thorough mixing, resulting in a consistent product.

- Milling and Homogenization: This step ensures the product has a smooth texture, free from gritty particles. It’s essential for patient comfort and therapeutic effectiveness.

- Cooling: Some products, especially those that contain waxes or high melting point fats, need controlled cooling to achieve the desired consistency.

- Filling: Once the semi-solid preparation achieves its final form, it’s filled into its packaging, be it tubes, jars, or sachets. Precision machinery ensures accurate and consistent filling.

- Quality Control: Before hitting the market, every batch is subjected to rigorous testing. Parameters like pH, consistency, active ingredient concentration, and potential contaminants are closely monitored.

- Packaging and Labeling: The final product is packaged and labeled, ensuring all regulatory guidelines are met, and the product information is clear to the end-users.

Challenges in Semi-Solid Manufacturing

- Consistency: Achieving a uniform texture and ensuring even distribution of the active ingredient is paramount.

- Stability: Over time, some semi-solid preparations may separate or degrade. Ensuring long-term stability is a continuous challenge.

- Scale-Up: Translating a lab-scale formulation to large-scale production without compromising quality is intricate.

Innovation in Manufacturing

Companies like Dow Development Laboratories stand at the forefront of semi-solid product manufacturing. Leveraging state-of-the-art technology and continuous research, they ensure the production of top-notch products that cater to both medical needs and consumer preferences.

The Environmental Consideration

Modern manufacturing is becoming increasingly conscious of its environmental footprint. Sustainable practices, green technologies, and waste minimization strategies are slowly becoming the norm in semi-solid product manufacturing.

A Glimpse into the Future

The semi-solid manufacturing landscape is poised for transformation:

- Smart Formulations: Imagine semi-solid products that change consistency upon application or those that release their active ingredients in response to skin conditions. The future holds a promise for such intelligent formulations.

- Eco-Packaging: As sustainability becomes a global priority, the packaging of semi-solids will also undergo an eco-friendly revolution.

- Tailored Therapies: With the rise of personalized medicine, we may soon see semi-solid preparations tailored to individual patient’s needs.

In wrapping up, semi-solid product manufacturing is a realm where precision, innovation, and quality converge. As technology and research advance, it’s evident that this segment will continue to evolve, promising better, more effective products for consumers worldwide.