Aug 7, 2023 | Articles

In the realm of pharmaceuticals, precision, innovation, and patient well-being are paramount. This landscape is where Dow Development Laboratories (DDL) emerges as a powerhouse, pushing the boundaries of topical drug product design and manufacturing. With an unyielding commitment to excellence, DDL’s journey is one of transformational impact in the world of medical solutions.

Unveiling DDL’s Specialization: Crafting the Future of Drug Delivery

At the heart of DDL’s expertise lies their ability to craft a diverse range of topical drug products. These formulations, including creams, gels, ointments, pastes, solutions, and suspensions, are meticulously designed to cater to various therapeutic needs. This remarkable versatility speaks volumes about DDL’s commitment to addressing a wide spectrum of medical requirements.

Formulating a World of Possibilities

One of DDL’s standout achievements is its capability to formulate across a vast range of compounds. From small molecules to peptides, proteins, new chemical entities, combination products, and generics, their expertise knows no bounds. This proficiency in working with diverse compounds showcases their adaptability and mastery of the intricate nuances of pharmaceutical development.

1. Designing Solutions for Diverse Needs

DDL’s journey begins with their specialized formulation design services. This phase entails blending scientific acumen with creativity to develop formulations that not only meet medical needs but also ensure patient comfort and convenience. The art of formulation design at DDL is a testament to their understanding that a well-crafted drug product is a harmonious fusion of science and patient-centeredness.

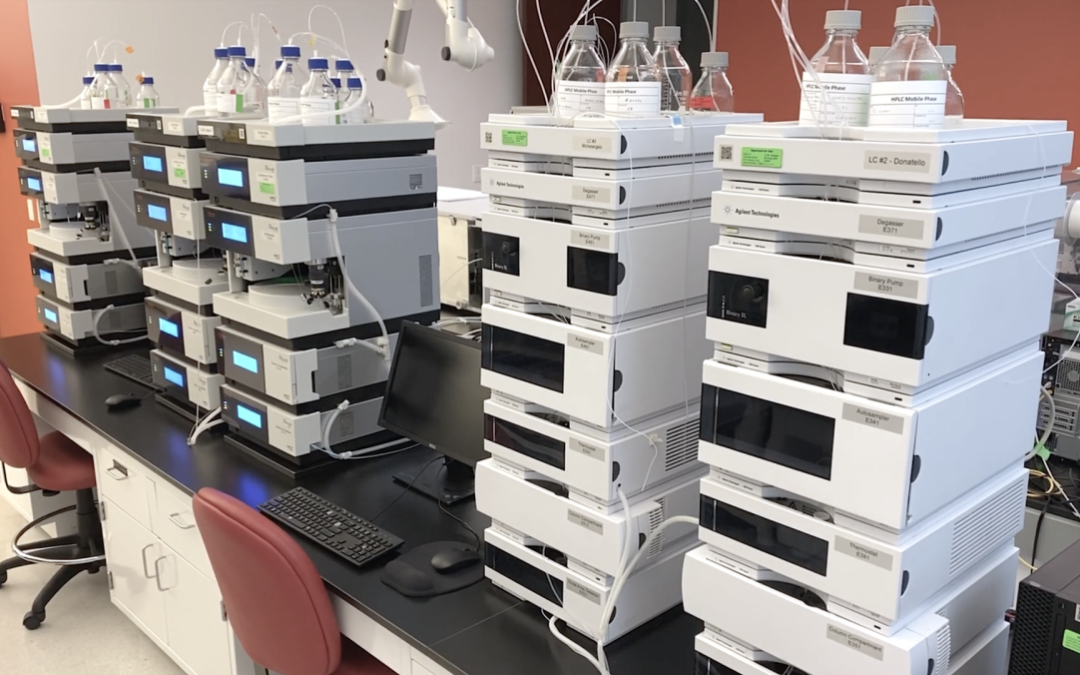

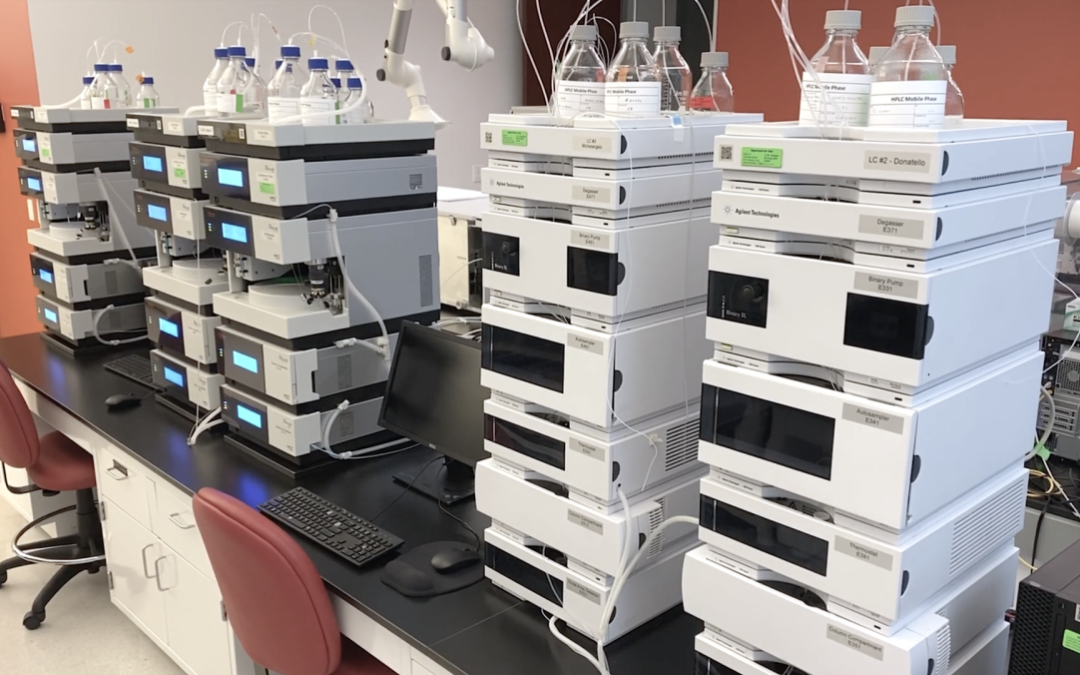

2. Precision in Manufacturing

The bridge from formulation to tangible product is manufacturing, and DDL navigates this with finesse. Their state-of-the-art facility, sprawling across 23,000 square feet in Northern California, is a testament to their commitment to precision and innovation. The facility’s FDA registration and cGMP compliance affirm their dedication to maintaining the highest industry standards.

3. Stability Studies: Ensuring Efficacy Over Time

In the pharmaceutical universe, stability is a non-negotiable attribute. DDL’s expertise in stability studies ensures that the formulated products retain their efficacy and safety over time. These studies provide critical insights into factors like shelf life and storage conditions, guaranteeing that the products are reliable and effective when they reach the hands of patients.

4. A Comprehensive Suite of Services

DDL’s prowess is not limited to formulation design and manufacturing. They offer a comprehensive suite of services that caters to every aspect of topical drug product development. This includes analytical methods development, process optimization, package compatibility assessments, and more. Their approach is holistic, leaving no stone unturned in the journey from concept to reality.

Patient-Centric Approach: QbD Principles and Beyond

Quality by Design (QbD) principles serve as the foundation of DDL’s approach. Every step, from formulation design to manufacturing, is meticulously planned to guarantee the utmost quality, safety, and patient-centricity. This approach underscores their dedication to ensuring that each drug product not only meets medical standards but also resonates with patient needs and comfort.

DDL’s Impact: Pioneering Innovations and Transforming Lives

DDL’s journey is an inspiring testament to the power of scientific excellence and innovation in the world of pharmaceuticals. Their ability to design and manufacture a diverse range of topical drug products, while maintaining the highest industry standards, is a hallmark of their commitment to transforming lives through medical advancements.

In an era where precision and efficacy are paramount, DDL stands as a beacon of pharmaceutical brilliance. Their expertise stretches across compounds, formulations, manufacturing, and beyond, culminating in medical solutions that redefine patient care. With every cream, gel, ointment, and solution that DDL brings to life, they leave an indelible mark on the landscape of medical progress.

Pioneering Excellence in Pharmaceuticals

In the intricate realm of pharmaceutical development, Dow Development Laboratories (DDL) is not just a company; it’s a symbol of excellence. Their ability to craft a diverse array of topical drug products, underpinned by unwavering dedication to precision and innovation, sets a gold standard for pharmaceutical advancement. As DDL continues to pioneer innovations and transform the world of drug delivery, their legacy as an industry leader is etched in the very fabric of medical progress.

Aug 2, 2023 | Articles

The realm of topical pharmaceuticals is dynamic and intricate, requiring a depth of expertise and precision in developing products that are both effective and safe for consumers. Engaging with a specialized Contract Development and Manufacturing Organization (CDMO) that focuses on topical pharmaceutical products is often the key to successfully navigating this complex field.

Harnessing Expertise for Development

A topical pharmaceutical CDMO offers a wealth of knowledge and expertise in the development of semi-solid and liquid drug products designed for topical application. These include creams, ointments, gels, and lotions, each carefully formulated to address specific skin conditions or enhance overall skin health. The developmental process is nuanced, with scientists and researchers meticulously working on creating formulations that provide optimal therapeutic effects while ensuring stability and aesthetic appeal.

Precision Formulation for Varied Applications

With a focus on addressing a diverse array of therapeutic indications, from dermatology to pain management, wound healing, and more, a topical pharmaceutical CDMO crafts formulations tailored to each application’s unique requirements. The process involves careful selection and balancing of active pharmaceutical ingredients (APIs) and excipients to achieve the desired therapeutic profile while maintaining product stability and user-friendly characteristics.

Advanced Manufacturing Capabilities

Upon finalizing the formulation, the manufacturing phase commences. A topical pharmaceutical CDMO boasts advanced facilities and equipment designed for the production of topical formulations, adhering to the highest standards of quality and compliance with Good Manufacturing Practices (GMP). Each batch produced undergoes rigorous quality control checks to ensure consistency and efficacy, meeting the predefined specifications and regulatory requirements.

Quality Assurance and Regulatory Navigation

Quality assurance is integral to the services provided by a topical pharmaceutical CDMO. The organization implements stringent testing and validation protocols to ensure each product aligns with quality standards. Additionally, these entities are adept at navigating the complex regulatory landscape, facilitating compliance with various health authorities’ guidelines and requirements, and supporting the smooth transition of products from development to market.

Conclusion: A Partner in Innovation and Quality

A topical pharmaceutical CDMO is a crucial partner for companies aiming to bring innovative and reliable topical products to the market. With a steadfast commitment to quality, compliance, and innovation, these organizations play a pivotal role in advancing the field of topical pharmaceuticals.

Entities like Dow Development Laboratories exemplify the capabilities and expertise inherent in a top-tier topical pharmaceutical CDMO, providing comprehensive services that span the gamut from formulation development to manufacturing and quality assurance. Through their concerted efforts, these organizations continue to push the boundaries of what’s possible in the topical pharmaceutical space, ushering in a new era of effective and dependable solutions for skin care and treatment.

Aug 1, 2023 | Articles

Jul 28, 2023 | Articles

The complex journey of topical drug development demands precision, expertise, and a deep understanding of both science and patient needs. A Contract Development and Manufacturing Organization (CDMO) focusing on topical drugs plays a pivotal role in this journey, steering the development and manufacturing processes toward delivering superior skincare solutions.

Foundation of Expertise

A CDMO specializing in topical drugs harbors a reservoir of knowledge, honed by years of experience in developing and manufacturing a variety of skincare products. The expertise embedded within these organizations allows for the creation of formulations that precisely meet therapeutic needs while ensuring safety and quality.

Development Precision

Crafting effective topical drugs begins with the accurate development of formulations. A topical drugs CDMO employs skilled scientists and formulators who meticulously work on developing products, paying keen attention to each ingredient’s role and interaction within the formulation. The process is thorough, involving in-depth research, experimentation, and testing to derive formulations that are potent, stable, and patient-friendly.

Focus on Quality Manufacturing

Manufacturing topical drugs with consistency and quality is a complex endeavor, and a specialized CDMO is well-equipped to navigate this challenge. With facilities designed for the compliant production of topical formulations, these organizations ensure that each product is manufactured, filled, and packaged with the highest standards of quality and efficiency.

Quality Assurance and Compliance

Integral to the operations of a topical drugs CDMO is a robust system of quality assurance. Each product is subjected to stringent testing and validation procedures, ensuring it meets all quality specifications and regulatory standards. The commitment to quality extends to ensuring compliance with regulatory bodies, facilitating smooth product approvals and market entries.

Conclusion: Enabling Skincare Innovation

Topical drugs CDMOs stand at the confluence of innovation and reliability, playing an essential role in bringing effective and safe skincare solutions to market. With a steadfast commitment to quality and excellence, these organizations enable the development and manufacturing of products that address various skincare needs and challenges effectively.

Entities like Dow Development Laboratories embody the spirit and capability of a premier topical drugs CDMO, offering a spectrum of services from concept to completion. Through their dedicated efforts and expertise, they significantly contribute to advancing the field of topical drugs, delivering products that make a positive impact on patients’ lives across the globe.

Jul 13, 2023 | Articles

In the realm of medical treatment, drug delivery methods have come a long way. Two methods that often raise questions are topical and transdermal drug delivery. While these terms might sound similar, they represent distinct approaches with unique mechanisms and applications. In this article, we’re going to delve into the differences between topical and transdermal drug delivery.

Understanding Topical Drug Delivery

Topical drug delivery involves applying medications directly onto the skin’s surface. The goal is to target a specific area, such as a skin condition or a localized ailment, while minimizing the impact on the rest of the body. Various formulations like creams, ointments, gels, and lotions are used to ensure effective drug absorption through the skin.

Mechanism: The skin is composed of multiple layers, with the outermost layer called the stratum corneum. Topical drugs primarily work by permeating this layer. They do not typically enter the bloodstream in significant amounts, thus minimizing systemic effects. Instead, they act locally, addressing the problem area directly.

Advantages:

- Localized Treatment: Topical treatments are ideal for conditions that require focused therapy, like skin infections, rashes, and minor wounds.

- Reduced Systemic Side Effects: The risk of systemic side effects is minimized as the drug doesn’t extensively enter the bloodstream.

- Ease of Application: Creams, ointments, and other topical formulations are easy to apply and convenient for patients.

Applications: Topical drug delivery finds its applications in dermatology (skin conditions), pain relief (local analgesics), and wound healing.

Exploring Transdermal Drug Delivery

Transdermal drug delivery, on the other hand, is a more specialized approach. It involves delivering medications through the skin and into the bloodstream for systemic effects. Transdermal patches are the most common form of this delivery method. These patches are designed to release a controlled amount of medication over time, ensuring a steady therapeutic dose.

Mechanism: Transdermal patches are made up of layers that control drug release. They are placed on the skin’s surface, and the medication permeates the skin’s layers to enter the bloodstream. This method allows the drug to bypass the digestive system, avoiding issues like stomach upset or metabolism by the liver.

Advantages:

- Consistent Drug Levels: Transdermal patches provide a consistent dose of medication over a specified time, leading to stable blood levels.

- Convenience: Patches offer convenience as they require less frequent dosing compared to oral medications.

- Systemic Treatment: Transdermal delivery is used for conditions requiring systemic effects, like hormone replacement therapy, nicotine replacement therapy, and pain management.

Applications: Transdermal delivery is used for hormonal therapies (contraceptives, hormone replacement), pain management (opioid patches), and smoking cessation.

In summary, the difference between topical and transdermal drug delivery lies in their intended effects. Topical delivery targets local issues through skin penetration, whereas transdermal delivery aims for systemic effects via controlled drug release into the bloodstream. The choice between these methods depends on the desired outcome of treatment. As medical research continues to advance, both approaches contribute significantly to enhancing patient care and quality of life.

Jul 12, 2023 | Articles