Solubility determination of the active pharmaceutical ingredient (API) in excipients suitable for topical use is a key first step in formulation development. The objective of most topical formulations is to have dissolved API so that the API can most effectively move from the formulation, through the skin layers to reach the site of action and does not precipitate in the formulation over the product shelf life. If the product is a suspension, the objective is to make sure the API remains unchanged, stable size and shape of particles, over the shelf-life. In-depth information on solubility uses in pharmaceuticals can be found in USP General Chapter <1236> Solubility Measurements | USP-NF1 as well as articles by Lubrizol2 and BASF3 on solubility.

Before beginning formulation development, a solubility study on the API is conducted to determine the best excipients that can solubilize and deliver the API to the site of action. The following factors are considered when designing a solubility study for an API for a topical product.

Structure and Size of the API

A careful look at the structure and size of an API helps determine what solvents to test in a solubility study. For example, long hydrocarbon chains are more hydrophobic. Thus, the API could be soluble or partially soluble in lipophilic solvents like most esters and mineral oil. Another example is that the API could be soluble or partially soluble in hydrophilic solvents like glycols and water if the API contains hydroxyl functional groups. However, functional groups are not the only factors that affect the solubility of an API. For example, itraconazole3 is an example of an API with a lot of polar moieties but is poorly soluble in water due to its high molar mass. Information typically found on an SDS is inadequate for product development use but can provide some clues.

Penetration Enhancers

Penetration enhancers, in the broadest sense include a wide range of pharmaceutical excipients such as propylene glycol and dehydrated alcohol, can help the API get to the site of action. How well any excipient actually helps the API penetrate into the skin depends on the formula as a whole.

Dosage Forms of Interest

An experienced formulation scientist will design a solubility study around excipients that work well in the desired dosage forms. For example, if the desired dosage form is a polyethylene glycol (PEG) ointment, the formulator can include PEG 400 or other glycols in the study. Another example is when considering the formulation of an emulsion: the API could be included solely in either the internal or external phase. While a formulator can have the API dissolved in both phases, they must consider any partitioning issues4 with the API.

Pick a Range of Solubilities

Pick a range of solubilities to include in a solubility study to build the most comprehensive solubility profile as possible for the API; this informs the formulator how the API could be soluble in similar excipients. For example, diethyl sebacate and diisopropyl adipate can have similar solubility for the same API due to their similar size and chemistry. Thus, the formulator could include only one in a solubility study. Hildebrand Solubility Parameters5 provide simple predictions of solubility based on a single parameter that can be obtained for many excipients and are mostly useful for nonpolar and slightly polar systems.

Use the IID to Select Excipients

The FDA’s IID List6 contains excipients used in approved prescription (Rx) products including the specific dosage form and maximum concentration. Thus, if the formulator has a desired dosage form, they can pick solvents based on other formulas on the market. Using IID excipients is beneficial to avoid additional toxicology work likely required for excipients not in approved Rx products.

Consider a Suspension if Needed

If the API is insoluble (or only slightly soluble) in the first set of solvents, the next considerations include: 1) doing another round of solubility studies with different solvents; 2) conducting another solubility study using mixtures of the solvents already tested; or 3) formulating vehicles that suspend the API rather than dissolve it.

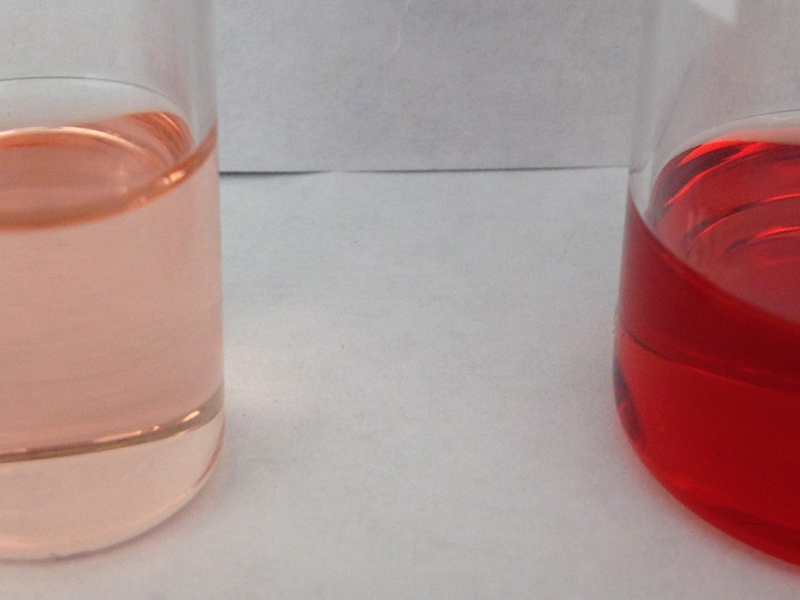

Solubility Determination

Studies can be designed in many ways depending on the parameters of the project. Typically, small amounts of API are added to an amount of solvent or solvent mixture until either saturation is reached or the target concentration for the drug product is achieved. These samples are then evaluated either visually and/or by UV spectrophotometry or HPLC.

For additional information about pre-formulation or solubility testing in topical product development, contact Dow Development Labs.

References:

- USP/NF Solubility Measurements <1236>

- “Solubility.” October 2019. Lubrizol Life Science.

- T. Reintjes. “Solubility Enhancement with BASF Pharma Polymers: Solubilizer Compendium.” October 2011. BASF SE.

- J. Puschmann, M.E. Herbig, and C.C. Müller-Goymann. “Influence of emulsifier concentration on partition behavior and chemical stability of betamethasone dipropionate in emulsion gels”, Int. J. Phar., 562, May 2019, pp 105-112.

- C.D.Vaughn. “Using solubility parameters in cosmetic formulation”, J. Soc. Cosmet. Chem., 36, 319-333 (September/October 1985).

- “Inactive Ingredient Search for Approved Drug Products.” January 2021. FDA/Center for Drug Evaluation and Research, Office of Pharmaceutical Quality, Office of Policy for Pharmaceutical Quality.