In the vast realm of pharmaceuticals, dermatological product manufacture occupies a space of undeniable importance. These skin-oriented products, ranging from lotions and creams to medicated gels and ointments, cater to a wide audience. Everyone, at some point in their life, requires dermatological care, whether it’s for a minor rash, acne treatment, or more severe skin conditions. But have you ever pondered the intricacies behind the manufacturing of these products? Let’s delve into the fascinating process of dermatological product creation.

Setting the Stage: The Need for Specialized Manufacturing

Skin is the body’s largest organ. It acts as the first line of defense against environmental aggressors, regulates temperature, and plays a significant role in sensation. Given its vital function, dermatological products need to be formulated with utmost care. The manufacture of these products requires specialized facilities, expertise, and rigorous quality checks to ensure the highest standards.

From Raw Materials to Finished Product: The Steps Involved

- Ingredients Selection: It begins with the careful selection of active and inactive ingredients. The active ingredients cater to the therapeutic need, while the excipients or inactive ingredients aid in product application, stability, and appearance.

- Formulation: This step involves creating a product prototype. The formulation is optimized for maximum efficacy, ensuring that the active ingredients penetrate the skin layers effectively. This is where the magic of science meets the art of crafting a product that users will love.

- Quality Testing: Before scaling up, the formulation undergoes a series of stringent tests. The product’s pH, viscosity, and stability are checked. The product is also tested for potential allergens or irritants.

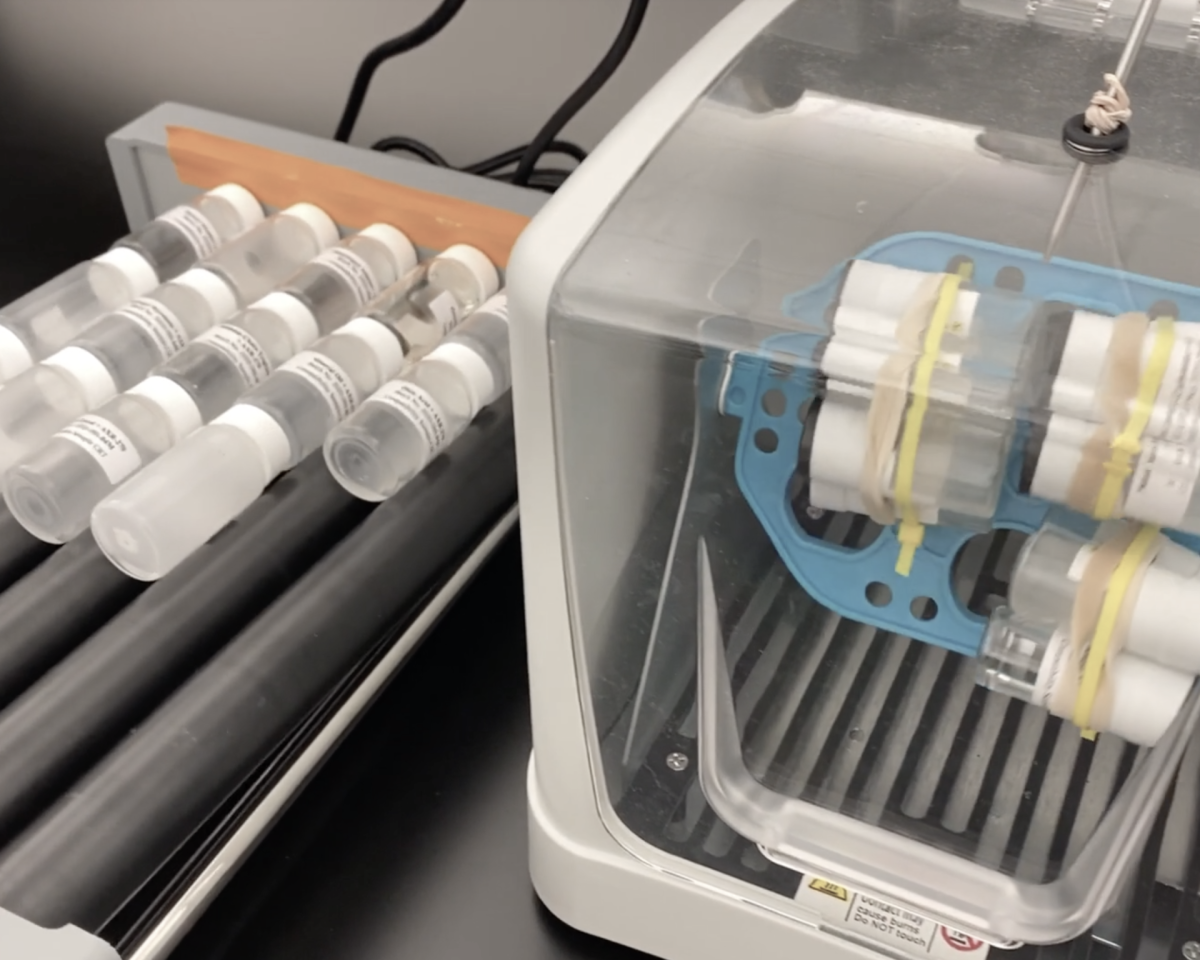

- Scale-Up & Production: Once approved, the formulation moves from the lab to the production facility. Using sophisticated machinery, the product is manufactured in large batches. During this phase, maintaining consistency is crucial. The product must remain homogeneous, with the same texture, color, and efficacy, regardless of the batch size.

- Packaging: Dermatological products are sensitive to light, air, and contaminants. Hence, the packaging is not just about aesthetics but also about preserving the product’s integrity. Tubes, bottles, and other containers are chosen based on the product’s consistency and usage.

- Final Quality Checks: Before the product reaches the consumer, it undergoes one last series of tests. These checks ensure that the product inside the packaging is free from contaminants and retains its therapeutic properties.

Challenges in Dermatological Product Manufacturing

While the steps might seem straightforward, the journey is fraught with challenges. The skin’s unique anatomy means that creating a product that penetrates effectively, without causing irritation, is a scientific challenge. Moreover, as consumer awareness grows, there’s a demand for products free from parabens, sulfates, and other controversial ingredients. Manufacturers need to constantly innovate, finding alternatives that are both safe and effective.

Conclusion

The next time you apply that moisturizer or medicated ointment, take a moment to appreciate the scientific marvel in your hands. The journey of dermatological product manufacture is a testament to human ingenuity and the relentless pursuit of better skincare solutions. As technology and research advance, we can only anticipate even more groundbreaking products that cater to our skin’s every need.