Nonsterile topical products must pass the USP/NF1 Microbial Examination of Nonsterile Products: Microbial Enumeration Tests <61> and Microbiological Examination of Nonsterile Products: Tests for Specified Microorganisms <62> and be adequately preserved.

A preservative, or a combination of preservative agents, is selected from the IID (FDA Inactive Ingredient Database) during formulation development. Preservatives include agents such as benzyl alcohol, methyl and propyl paraben, phenoxyethanol, and sorbic acid. Factors that may influence the choice and the strength to be used include the formulation ingredients, dosage form and pH, as well as the active pharmaceutical ingredient (API) (e.g., it may be that the API has preservative activity or that the API is harmed by preservatives).

Microbial Limits Tests (MLT) – used for product release

MLT, also known as Microbial Enumeration Tests (MET), is used as a release test for non-sterile topical products. The standards as defined in USP chapters [61] and [62] are harmonized for US, European, British and Japanese markets. The testing includes both a quantitative and a qualitative phase. The quantitative phase [61] determines the total number of aerobic organisms and the total number of yeast and molds present. The qualitative phase [62] tests for the absence of specific objectionable organisms based on the product’s intended use, see USP [1111].

The USP/NF test methods need to be validated for the product vehicle as well as for the high strength product before product testing can be conducted. If antimicrobial properties are present in the formulation, the Method Suitability Test will determine the necessary dilutions, filtration, and neutralization required to test the product.

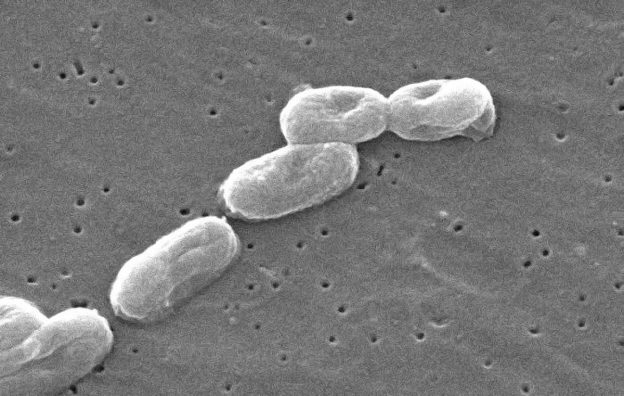

Burkholderia cepacia complex (BCC) – a recent change

Even with antimicrobial preservatives in place, opportunistic pathogens can contaminate a product. Aqueous preparations of oral, oromucosal, nasal, and cutaneous products are susceptible to contamination from the Burkholderia cepacia complex (BCC). BCC complex consists of 17 closely related gram-negative aerobic bacteria found in soil and water. BCC is known to form a highly resistant biofilm that can stay viable in harsh conditions for long periods and is resistant to many antibiotics. FDA has advised drug manufacturers of the risk of BCC contamination2.

Due to the increased scrutiny for patients posed with high medical risk, USP recently created a new chapter with testing guidelines to ensure BCC’s absence in regulated products. The chapter, USP <60>, specifies the test strains for growth promotion, suitability methods, and selective media. The chapter works in conjunction with the existing chapters for MLT testing, USP <61> and USP <62>.

Antimicrobial Effectiveness Testing (AET) – an important part of a stability program

Microbes can be unintentionally introduced to the product during the manufacturing, filling or through continual use of the product. To determine if the preservative system is effective, preservative efficacy testing (AET) should be carried out as part of a stability study to establish that the preservative system is effective for the entirety of the proposed shelf life. AET testing is performed in accordance with USP <51>. The test is performed by spiking a panel of challenge microorganisms into the product and determining the log reduction of organisms at prescribed time intervals.