The realm of pharmaceuticals is vast, encompassing a wide variety of product types from oral pills to intravenous solutions. Among these, topical drug products stand out, offering unique challenges and rewards for those involved in their manufacture. Topicals, which are designed for direct application to the skin or mucous membranes, include a range of formulations such as gels, creams, ointments, lotions, and patches.

Laying the Groundwork: Key Considerations

Manufacturing topical drug products is not a straightforward process. The journey from concept to finished product is rife with meticulous planning, rigorous testing, and strict regulatory compliance.

- Targeted Formulation: Each topical drug product is formulated for a specific therapeutic indication. This requires a clear understanding of the ailment it’s designed to treat and the active ingredients that will provide therapeutic relief.

- Skin’s Barrier Function: The skin is nature’s protective shield, keeping harmful entities out and maintaining essential bodily functions. Ensuring that a topical product is absorbed efficiently while retaining its efficacy is a complex challenge.

- Stability and Shelf Life: A well-formulated product must remain stable, maintaining its integrity and efficacy throughout its stated shelf life, under various conditions.

- Cosmetic Appeal: Beyond medical efficacy, the feel, scent, and appearance of a topical product can significantly influence patient compliance.

In the Lab: The Manufacturing Process

The intricacies of manufacturing topical drug products vary based on the specific formulation type. However, the overarching process can be outlined in broad strokes:

- Raw Material Selection: This is the first and perhaps most crucial step. The active ingredients, excipients (non-active ingredients), and any preservatives or stabilizers must be chosen with care. Quality control starts here, ensuring each material is of the highest standard.

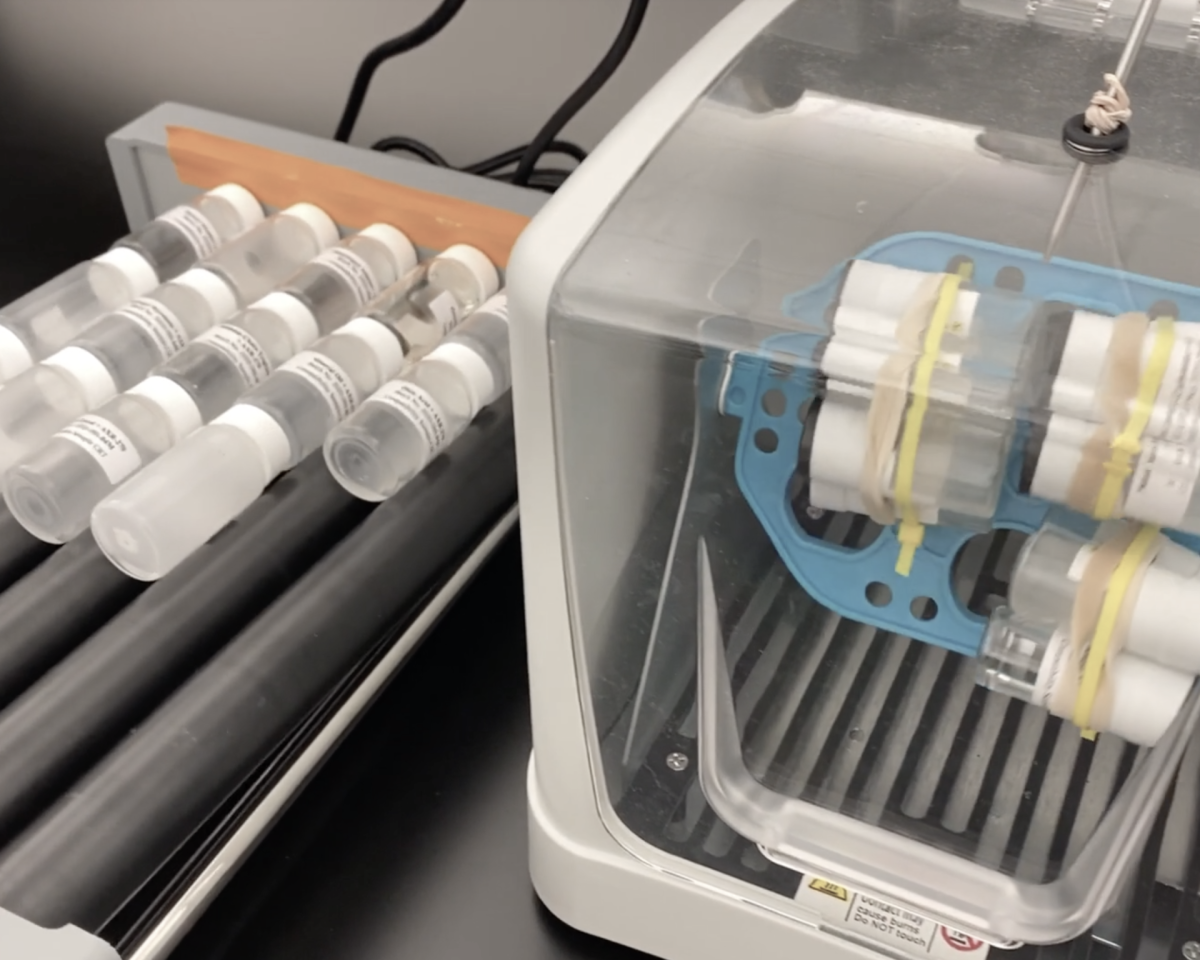

- Mixing and Production: The actual manufacturing phase where ingredients are combined, often in specific sequences and under controlled conditions, to produce a homogeneous product. The methods vary, from simple mixing for creams and lotions to more complex procedures for patches and other advanced delivery systems.

- Filling and Packaging: Once produced, the product needs to be filled into its final packaging, whether it’s tubes, bottles, syringes, or sachets. This step might seem straightforward, but ensuring the product remains uncontaminated and consistent in quality is vital.

- Quality Control and Assurance: Samples from each batch undergo rigorous testing to ensure they meet predefined quality standards. This includes tests for consistency, pH, viscosity, and, most importantly, the concentration of the active ingredient.

Staying Compliant: Regulatory Oversight

The world of pharmaceuticals is heavily regulated, and for a good reason. Patient safety and efficacy are paramount. Manufacturing facilities must adhere to Good Manufacturing Practices (GMP), a set of guidelines that ensure consistent quality and safety in production.

Ensuring compliance goes beyond following a set of guidelines. It’s about cultivating a culture of excellence and accountability, where every individual understands the profound impact of their role on patient health.

Pioneers in the Field

Companies like Dow Development Laboratories are at the forefront of topical drug product manufacture. With their state-of-the-art facilities and seasoned teams, they’ve carved a niche in producing topicals that meet both clinical and consumer needs.

Their approach, which combines rigorous scientific methodologies with an understanding of consumer preferences, has set new standards in the industry. By considering not just the medical implications but also the product’s real-world usage, they have successfully bridged the gap between therapeutic efficacy and user acceptability.

Peering into the Future

The landscape of topical drug product manufacture is continually evolving. With technological advancements and a deeper understanding of skin physiology, the horizon holds immense promise. We can anticipate more personalized formulations, improved delivery systems, and products that cater to a broader spectrum of skin types and conditions.

Furthermore, as sustainability and environmental concerns take center stage, the manufacturing processes will inevitably need to adapt, paving the way for greener and more eco-friendly production methods.

In wrapping up, the world of topical drug product manufacture is a delicate balance of science, art, and responsibility. It’s an arena where the lines between medicine, cosmetics, and user experience blur, producing products that have the power to transform lives, one application at a time.