Topical pharmaceutical product testing is a pivotal aspect of ensuring that the skin-based treatments reaching consumers are safe, effective, and reliable. In the vast sphere of pharmaceuticals, each product designed for topical use undergoes rigorous testing procedures that scrutinize its various attributes before it can be deemed ready for use.

Embarking on the Testing Odyssey

The journey of topical pharmaceutical product testing begins once the development phase is complete and prototypes are available. This stage is critical as it sets the benchmark for the product’s quality and effectiveness, serving as the gatekeeper that ensures only the best formulations make it to the market.

Ensuring Active Ingredient Potency

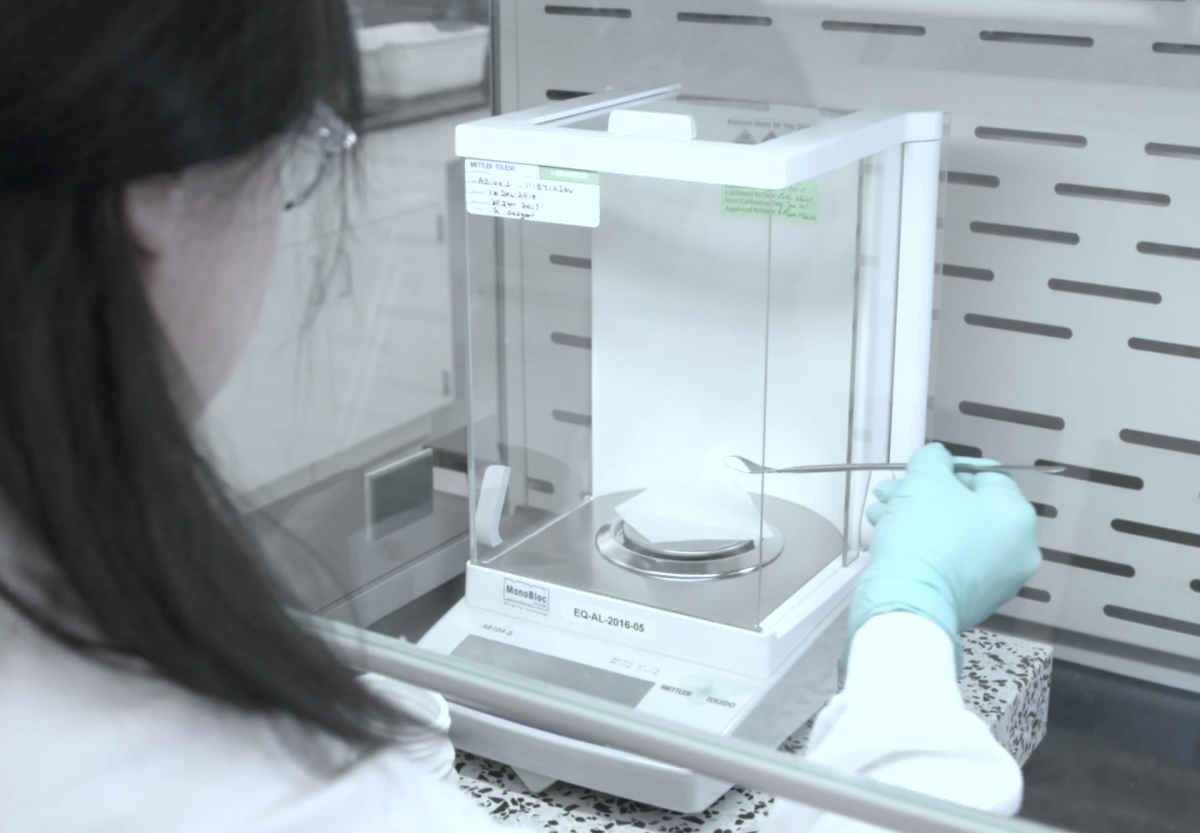

The active pharmaceutical ingredient (API) is the lifeblood of any pharmaceutical product. Testing laboratories engage in quantitative assays to ensure that the API and related substances in the formulation are present in the right amounts. It’s crucial to confirm that the API maintains its potency and stability during the manufacturing process and throughout the product’s shelf life.

Verifying Preservative Efficiency and Stability

Topical formulations often contain preservatives to enhance their shelf life and prevent contamination. Through quantitative assays, testing procedures ensure these preservatives are effective and present in the formulation at optimal levels. This process is essential for the product’s longevity and safety.

Analyzing Physical Characteristics

A series of tests are conducted to analyze the physical attributes of the product, such as pH, viscosity, appearance, and water content. These attributes significantly influence the product’s performance and user experience, making their analysis crucial in topical pharmaceutical product testing.

Performing Advanced Analytical Testing

Advanced equipment and methodologies, like High-Performance Liquid Chromatography (HPLC), are employed to perform detailed analytical testing. These techniques allow for a deeper understanding of the formulation, providing insights into the product’s stability, composition, and other critical factors.

Package Compatibility Testing

Given that packaging plays a vital role in preserving the integrity of the pharmaceutical product, compatibility tests are conducted to ensure that the packaging material does not react with the product, thereby maintaining its stability and efficacy.

The Keystone of Quality Assurance

Topical pharmaceutical product testing is an intricate and vital process in the lifecycle of skin-based treatments. It stands as a pillar of quality assurance, validating that every product released into the market meets the stringent standards of efficacy, safety, and quality.

In the landscape of pharmaceutical development, organizations dedicated to topical product testing, like Dow Development Laboratories, engage in these meticulous processes with a commitment to excellence and precision. With their expertise and the advent of advanced testing technologies, the future of topical pharmaceutical products is not only promising but also assures a legacy of trust and reliability for consumers worldwide.